For 35 years, we’ve lived and breathed conveying technology and everything associated with it, and nothing else piques our interest quite the same. From traditional tube chain conveyors, through mobile conveyor systems, all the way to perfectly coordinated bulk material handling, we have the right solution for you.

The Schrage family.

We’re an owner-managed family enterprise, and that means that we see our family not only as including our employees, but our customers and suppliers as well. That’s why trust, dependability, responsibility, honesty, and respect are the foundation of what we do and our commitment to getting the best results out there unites us all.

WE MAKE IT SHORT AND SIMPLE

If it's well filmed it's well explained:

If it's planning and production processes, team management or installation work, using and setting up our conveying and handling systems:

Clips by Schrage are our no-frills solution that deliver quick responses and spot-on explanations.

For our video experience we had one key aspect in mind: we wanted it to be simple!

Passionately sustainable.

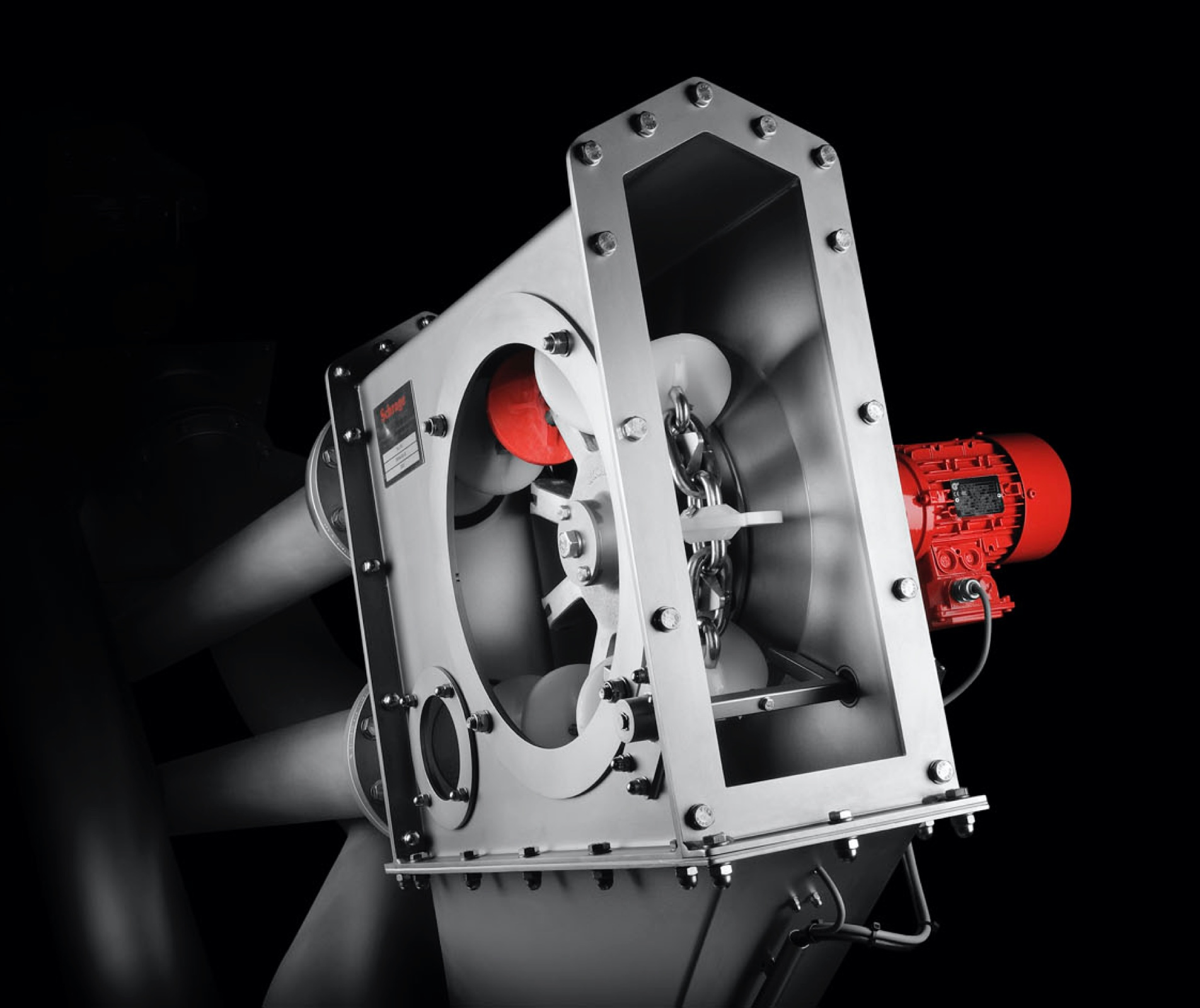

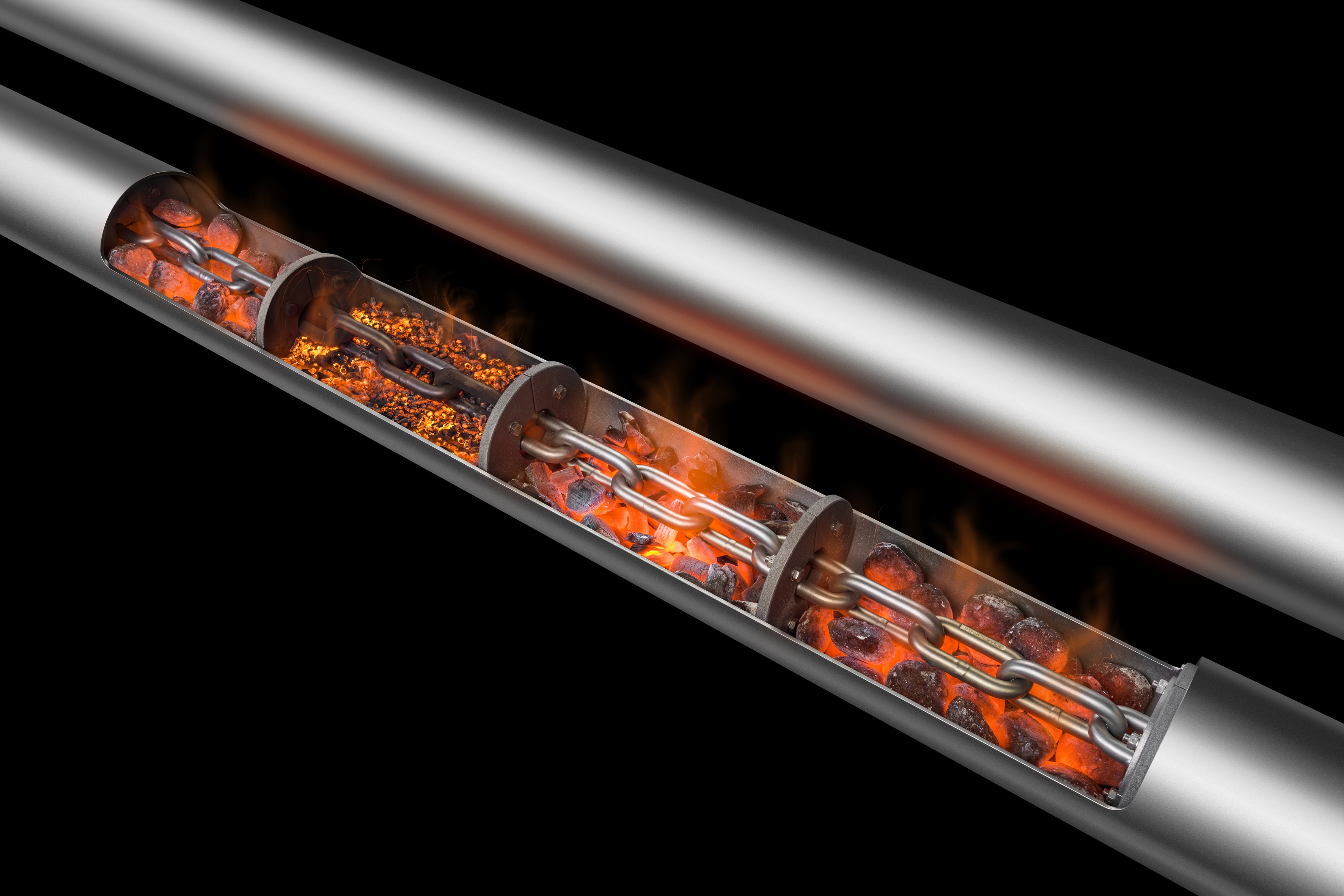

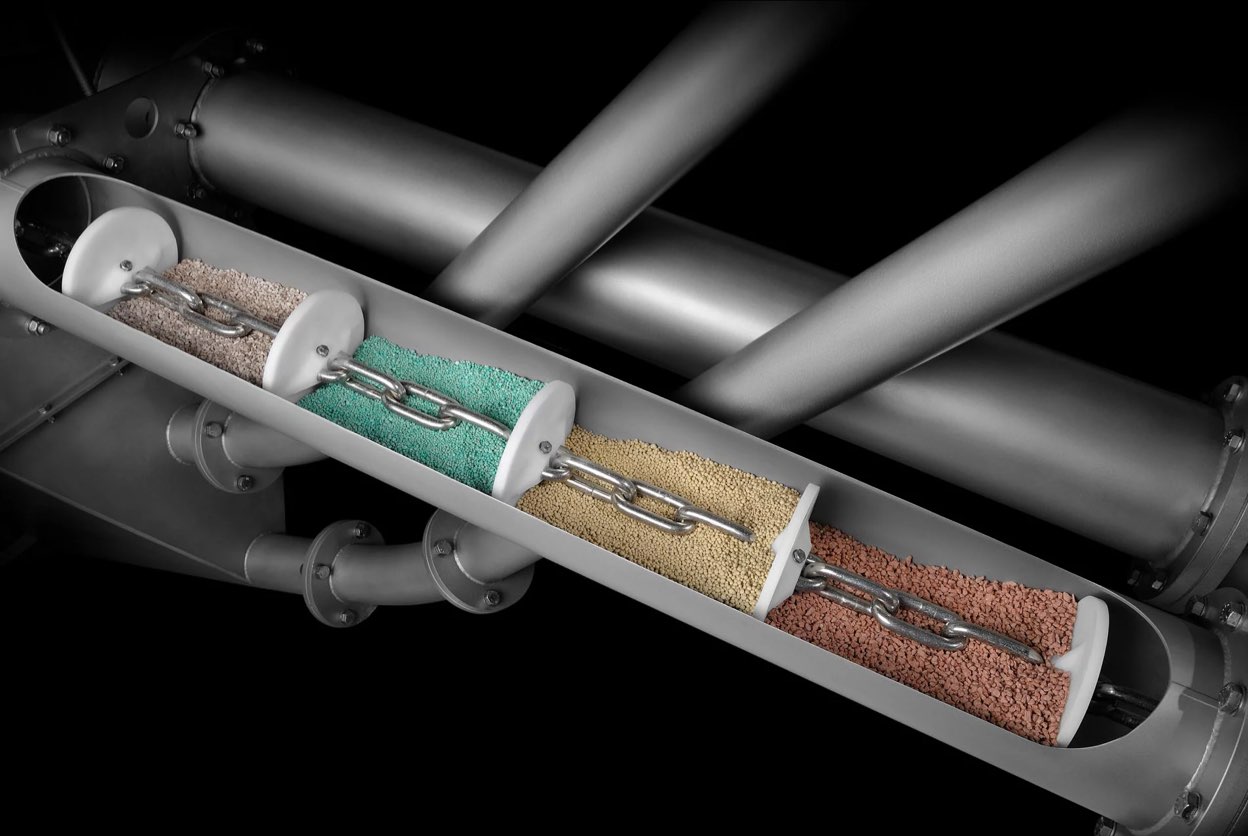

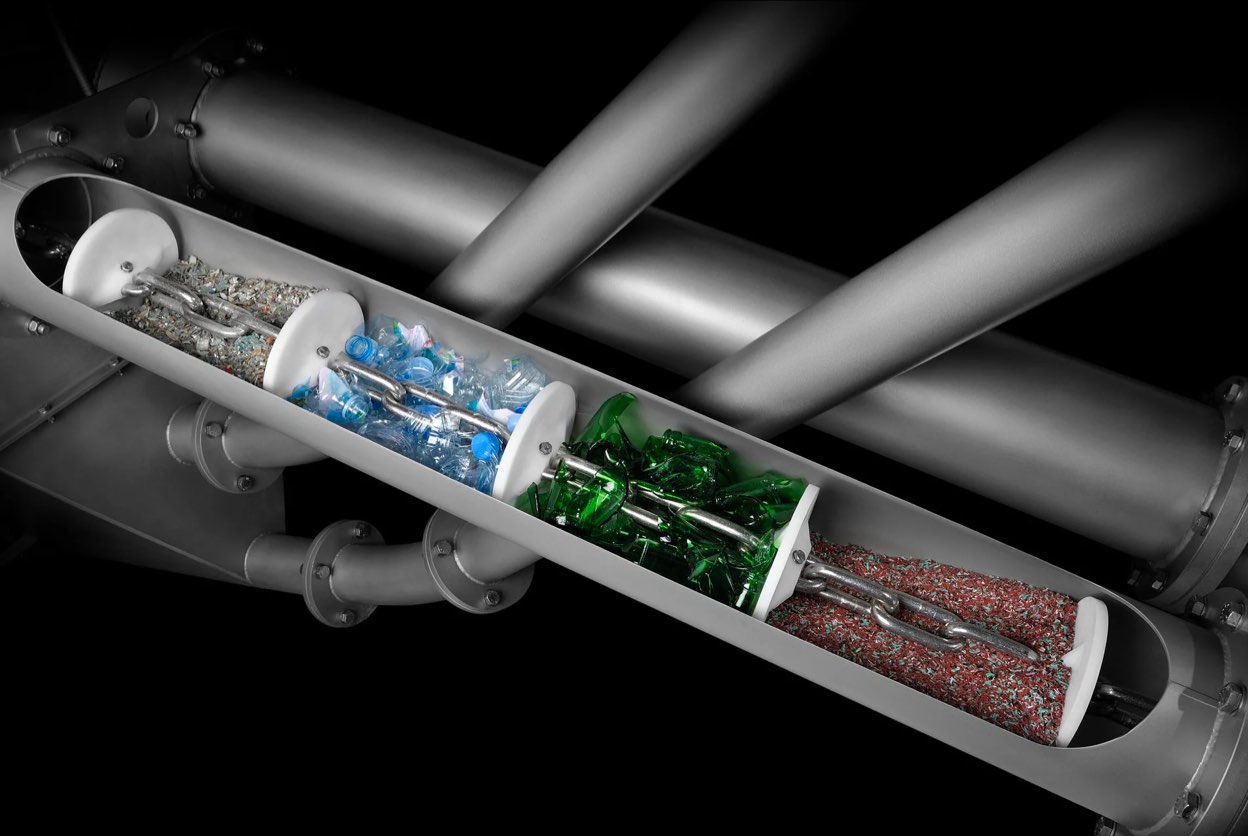

Sustainability is something that we’ve valued for a long time, as durability and future-proof solutions have been as much a part of the Schrage philosophy as a heartfelt passion for our products since our foundation. Low power consumption, low-wear components, and sturdy products are all ways in which we’re there for you and our environment.

We get things moving for you.

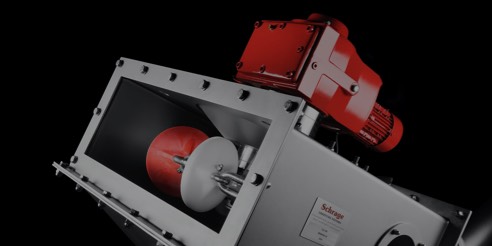

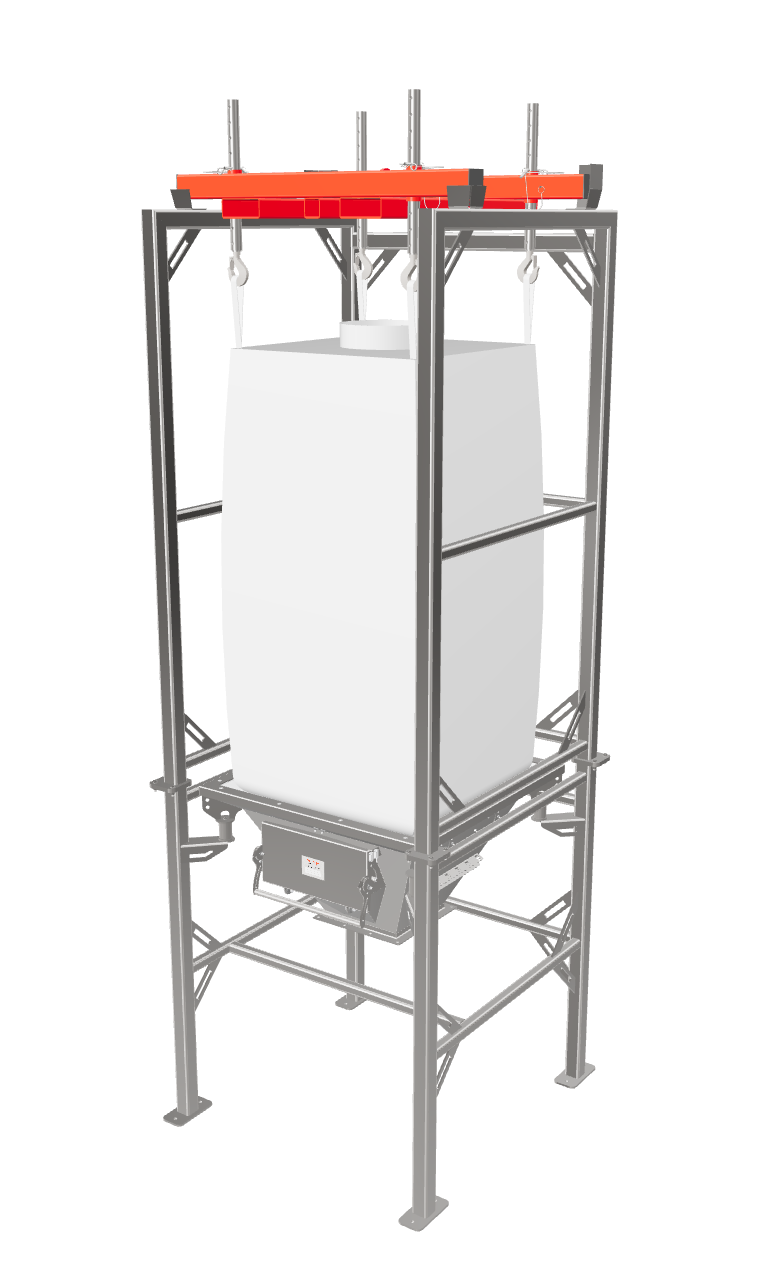

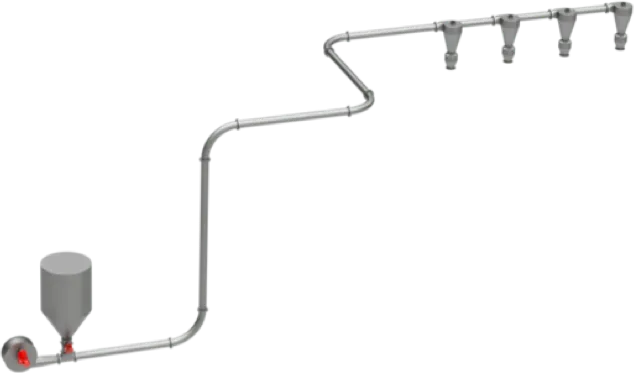

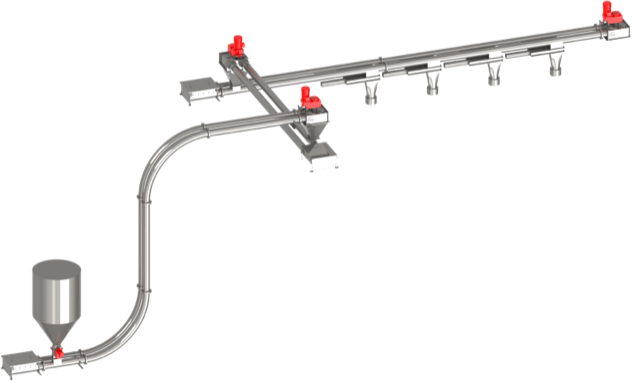

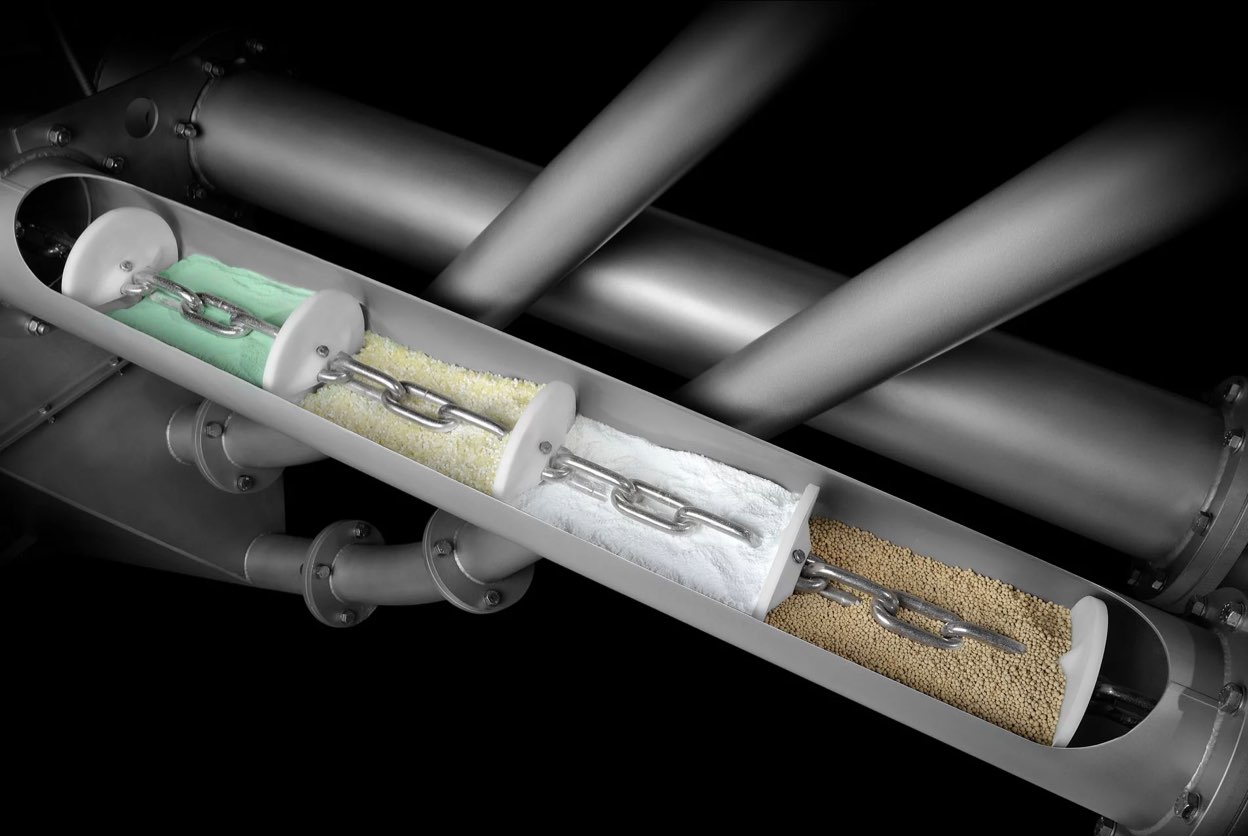

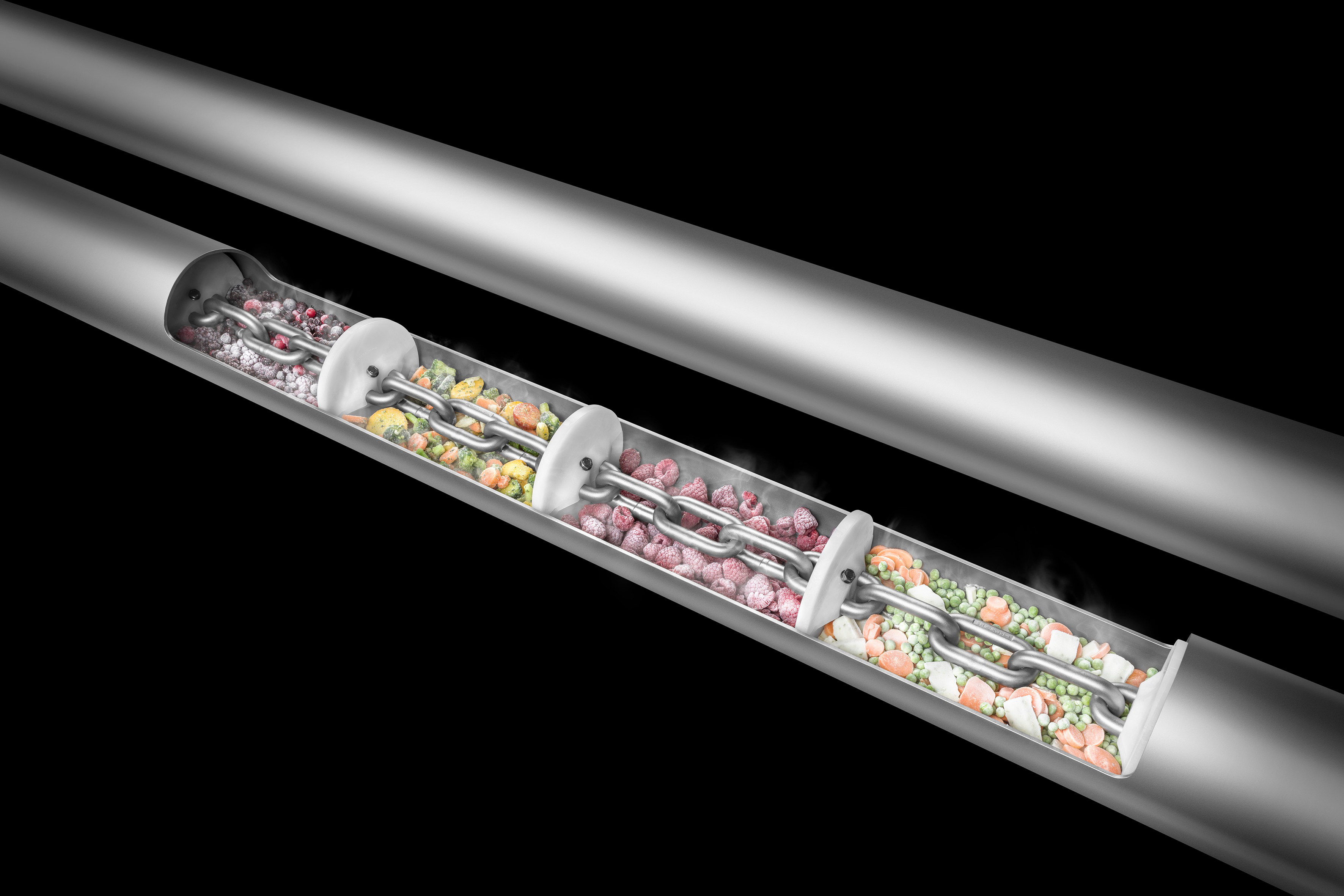

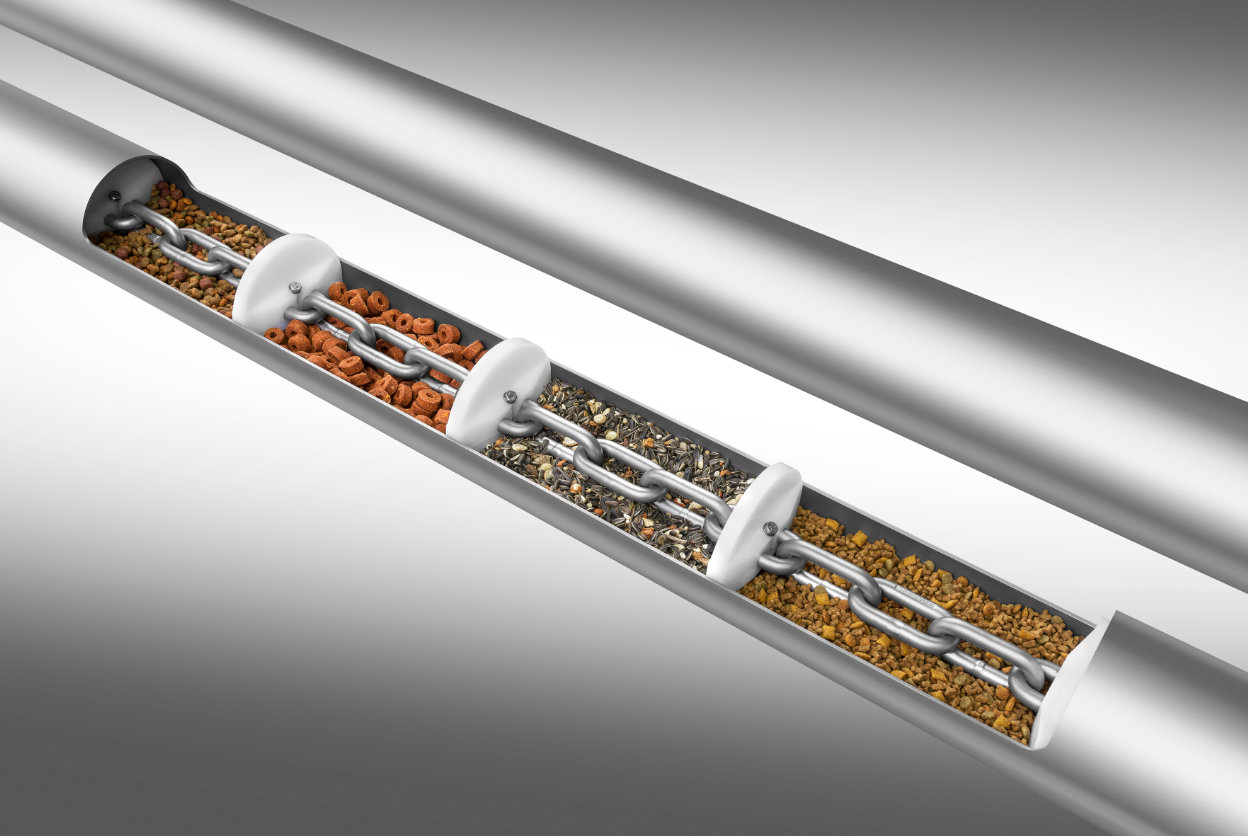

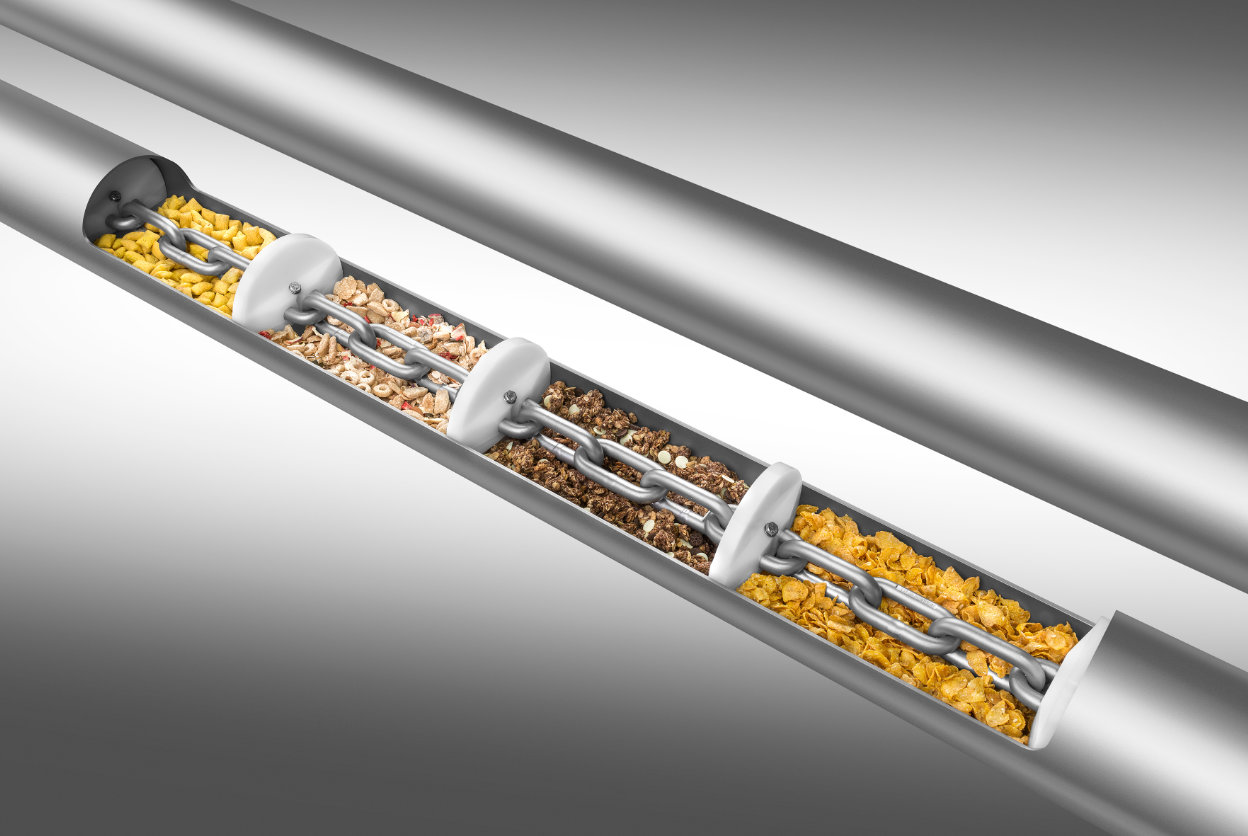

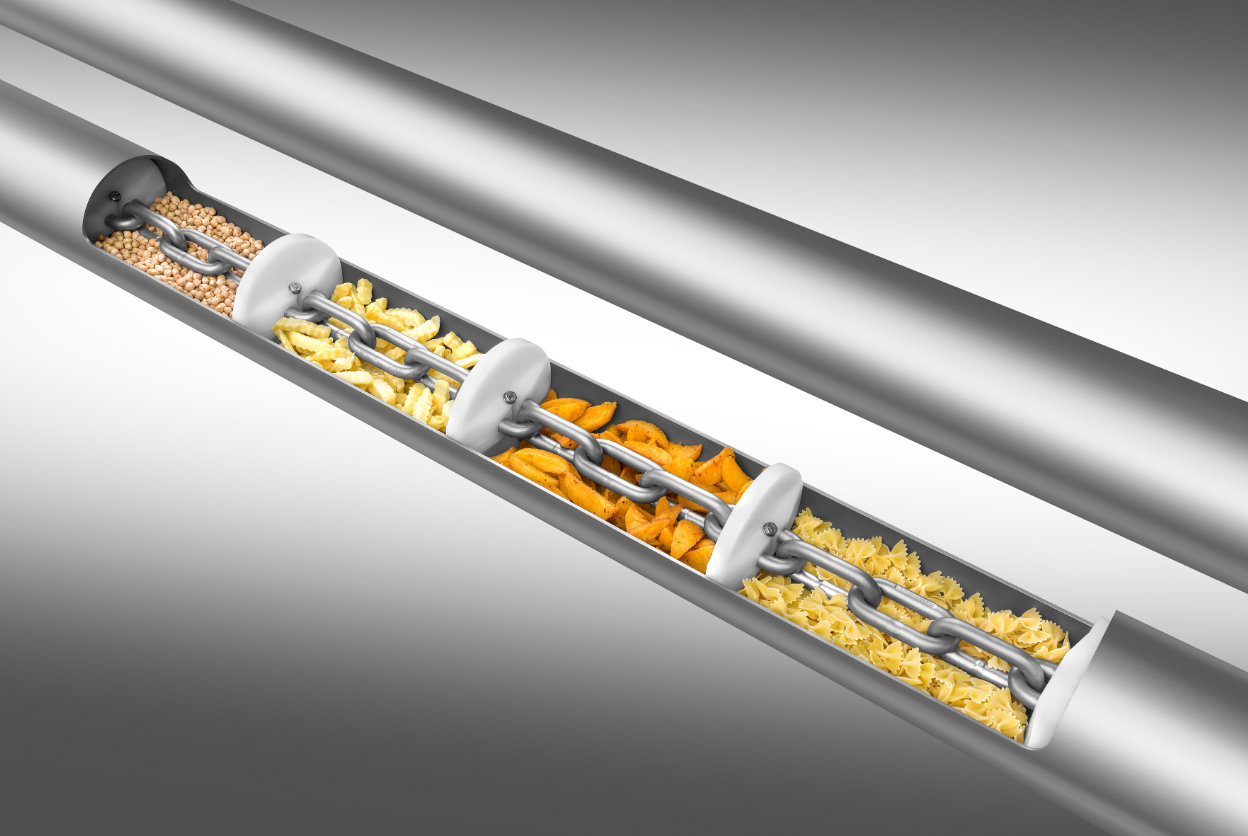

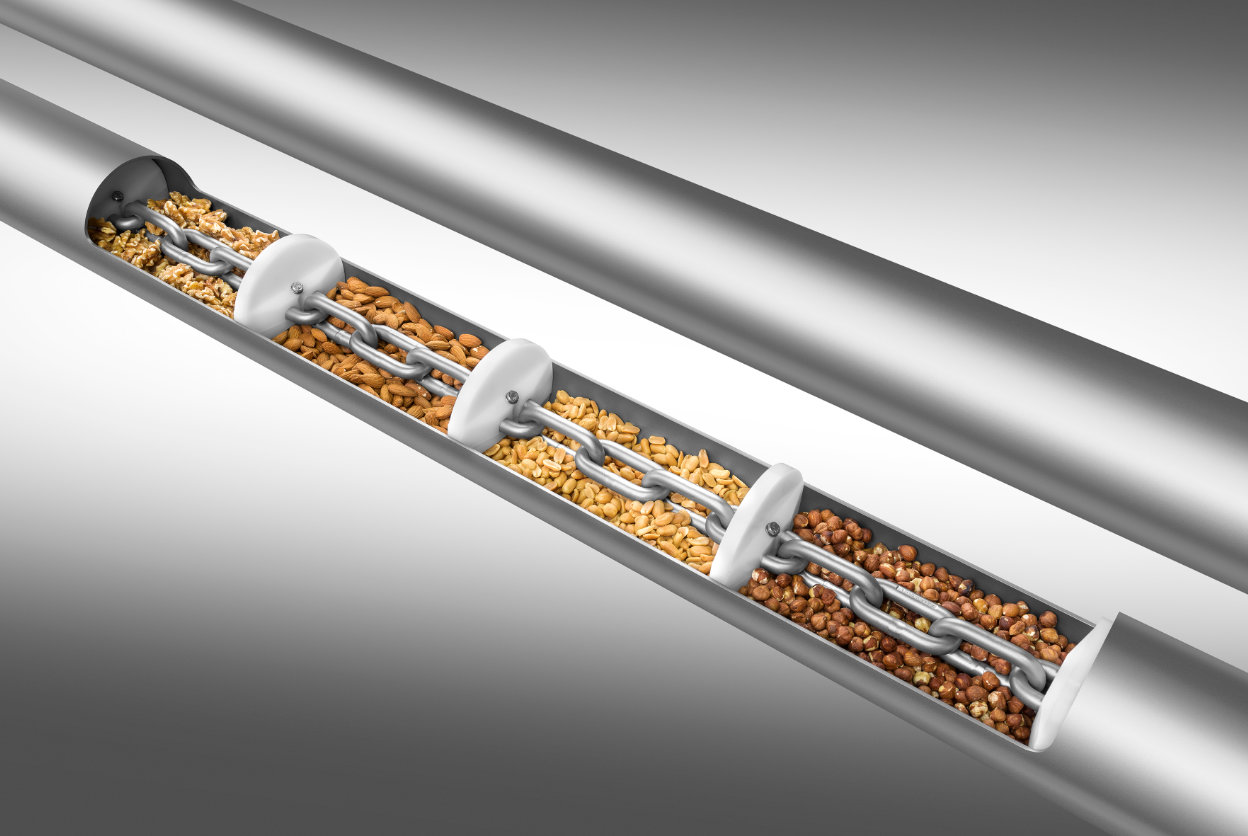

Our tubular drag chain conveyors are in use across the whole globe. It should come as no surprise then that we offer the right solutions for an extremely wide variety of industries and are experts in making sure that your bulk materials are conveyed smoothly and without any loss. Following is a selection of the areas where our products are used.

Extras &

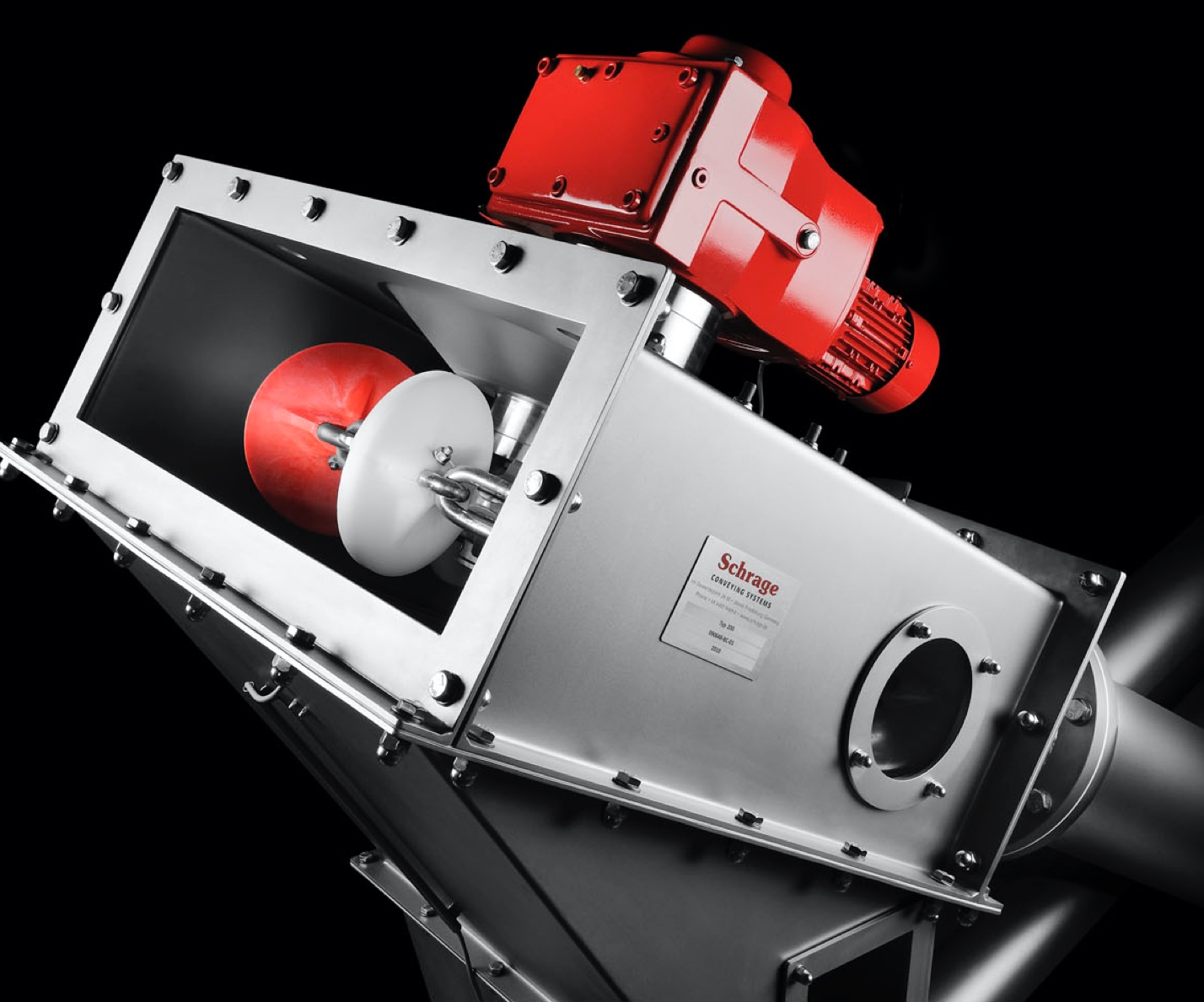

accessories

Regardless of whether you need shut-off, chain tensioning, redirecting, or cleaning systems: Our systems can be customized and expanded further at any time in order to meet your needs down to a T. We’re there for you at all times and will make sure that your processes run smoothly.