Company

Unternehmensphilosophie

Our corporate philosophy at

Schrage Conveying Systems GmbH

Team spirit drives us: We promote solutions - with heart & mind.

The mission behind it? Find out more here!

Technical center

We never leave anything to chance! That’s the existential reason of our Schrage Technical Center: Simply send us a sample of your bulk material and we’ll document our tests on video for you. Or come by so that we can find the right tube chain conveyor for you together – after all, you’ll be using it later on.

We’ll run wear tests to identify the perfect material combination for your system: for the conveyor discs, for the conveyor chain, and even for the enclosure (tubes and bends). At the end of the day, we always make sure there’s no stone left unturned!

Every bulk material is different: Do you know your own value?

Are you aware of all the properties of the product that you would like to transport? Bulk materialis not just bulk material! Successful conveying methods are not necessarily transferable to other materials. We always start with analysis.This helps us to determine the extent of the challenge and enables us to deliver swift and accurate responses to your enquiries. Material characteristics, for example …

Tests! Tests! Tests! But does it work?

That is precisely what we need to know before we plan a layout configuration! You will also profit from a solution that has been based on your specific bulk material and circumstances from the outset.

That is why we are rarely satisfied with mere material tests. The Schrage test facility enables us to conduct conveyor tests under realistic conditions, in which we would be delighted to welcome you to Friedeburg so that we can demonstrate our working tube chain conveyor models.

It runs and runs and runs ...

Test runs and long-term testing

Even a conveyor test is sometimes not enough. To find out exactly how your specific material will react under various conditions, we can conduct test runs with your bulk material at our own technology center.

We will even offer to provide you with product-specific test machinery so that we can conduct site-oriented long-term research. That is better than any laboratory test run because a one-to-one test answers many important questions and delivers the data that we need during the subsequent planning phase.

Therefore, go ahead and test what we can do for you.

Production.

We make, machine, assemble, and ship our systems right in our home in Friedeburg: Schrage quality from Germany all the way down to the smallest detail. That’s how we make sure that we meet the increasingly stricter requirements of a broad range of industries while letting you benefit from the closeness of all our operations. The custom products developed by our engineers are built, tested, and packed for global shipping right next door. And that’s what we call a true location advantage. In fact, all our teams work perfectly together the same way our conveyor systems do.

Showroom.

Everything there is to know about Schrage conveying technology can be found in a compact format at our showroom in Friedeburg. The entire Schrage tube chain conveyor portfolio, including accessories, is set up there for visitors – as a microcosm of bulk material handling technology, if you will. And we’ve done everything to make sure that we can showcase our conveyor systems in operation and as hands-on as possible for you: bulk material handling in living color.

These accolades show that we take customer satisfaction rather seriously. The things that we do every day to make ourselves a little bit better are published in a quality management guide for all to see.

Because we can prove that our quality is of the highest standard with DIN EN ISO 9001, you are not requested to just take our word for it.

A close relationship with universities, universities of applied science and industry associations constantly expands our knowledge about the conveyance of bulk materials. Our curiosity and our ambition drive us forward and enable us to tirelessly research and optimise our products, ensuring that our customers can be absolutely sure of the quality of our products.

We make our quality visible. The CE marking of our tube chain conveyors clearly shows that the conformity of our systems corresponds to the requirements of the European Union.

With the CE marking, we declare that our tube chain conveyor, as an individual installation, fulfills all the applicable community rules and that all mandated conformity assessment procedures (such as risk assessment, hazard analysis, and verification of compliance with the standards) have been carried out.

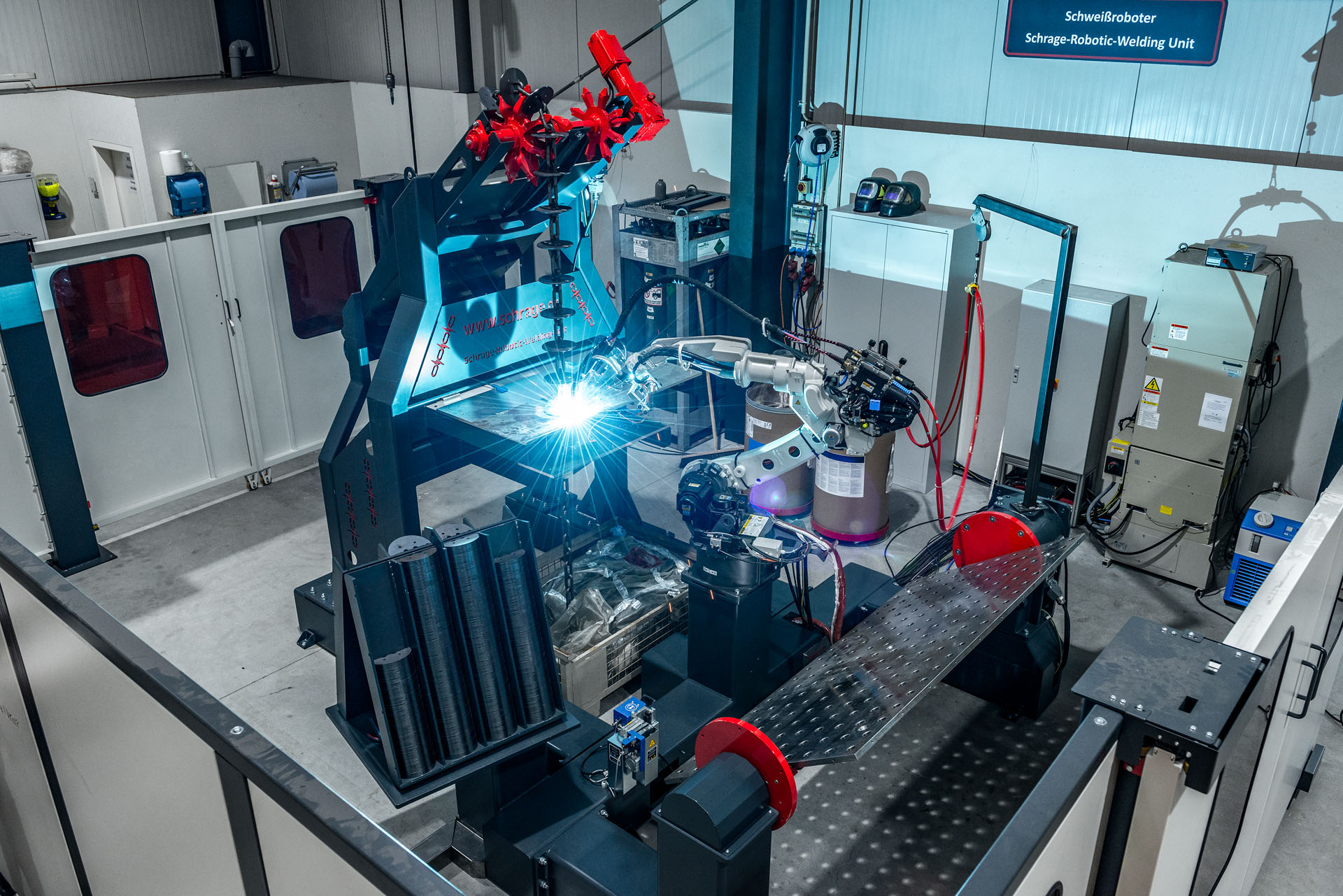

Now it is official: We fulfill all the quality requirements according to the DIN EN ISO 3834 series of standards for the production of fusion-welded components and structures. This includes welding during made-to-order production as well as during assembly and service. This is yet another contribution on our part to the quality assurance of our products.

This is another certificate for plants or equipment used in production facilities in Russia with a high risk profile.

The RTN permit is issued by the Federal Service for Ecological, Technological, and Atomic Supervision ROSTECHNADZOR (formerly GGTN – GOSGORTECHNADZOR).

The certificate proves that our tube chain conveyors are not subject to this permit and, therefore, they do not require the certificate.

The EAC certificate confirms that our tube chain conveyors have been presented to an accredited authority of the customs union and that they comply with all the technical regulations. It is proof that our conveyor systems fulfill the minimum requirements and do not require certification as per TR-ZU. It is valid in Russia, Republic of Belarus, and Kazakhstan.

...is not a certificate, but rather a directive that Schrage also uses at their location in Friedeburg, Germany: The ATEX directive 2014/34/EZ (previously 94/9/EG or “ATEX 95”) defines the regulations for putting into circulation products for use in environments with explosive atmospheres. It serves the purpose of protecting those who work in such environments. Therefore, the directive stipulates the fundamental health and safety requirements which must be met by the manufacturer. Here at Schrage, not only do we work in compliance with this directive, but we also fulfil the quality assurance system for the manufacturing, final acceptance and testing of conveyor systems and components which will be used in environments with explosive atmospheres.