Schrage vs. the rest of the world

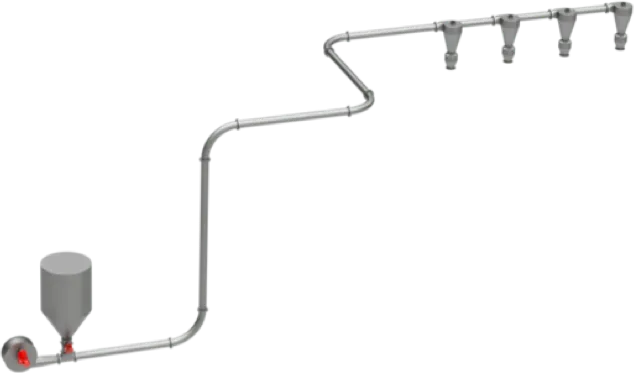

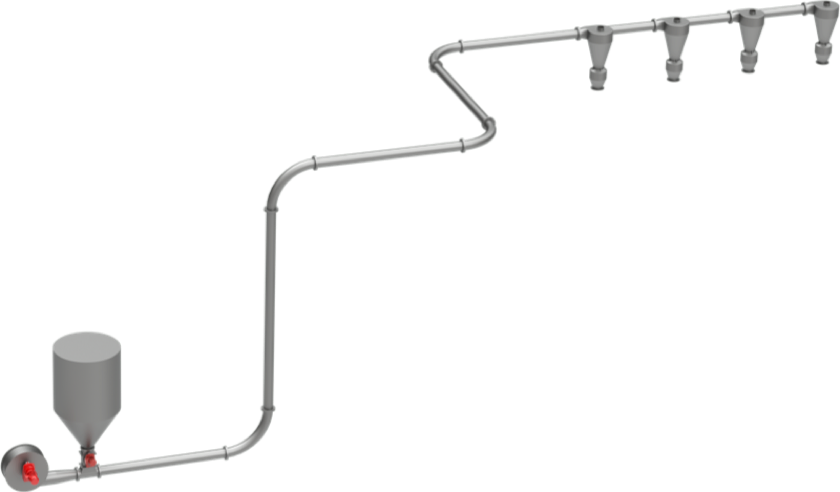

Pneumatic conveyor systems

- A length of 90 meters can be implemented with a single line

- Multiple cyclone separators required

- Tons of measuring and control equipment

- High air speed, resulting in greater wear and grain destruction

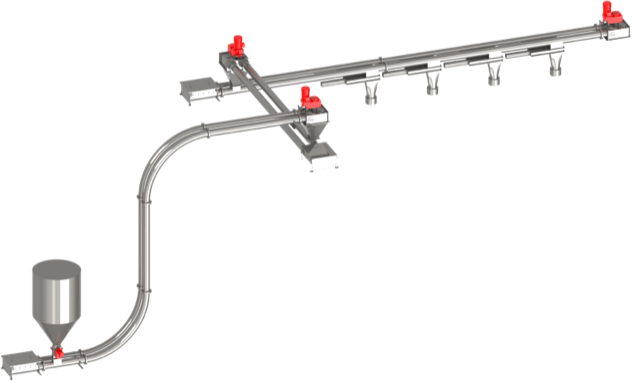

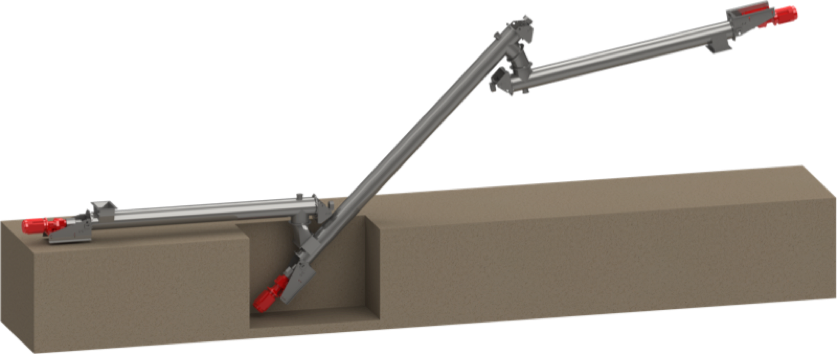

Tube chain conveyor

- Three tube chain conveyors are required for this line layout (90 meters)

- Low conveying speed, resulting in minor wear and grain destruction

- No filter systems or cyclone separators required, meaning that very little measuring and control equipment is required

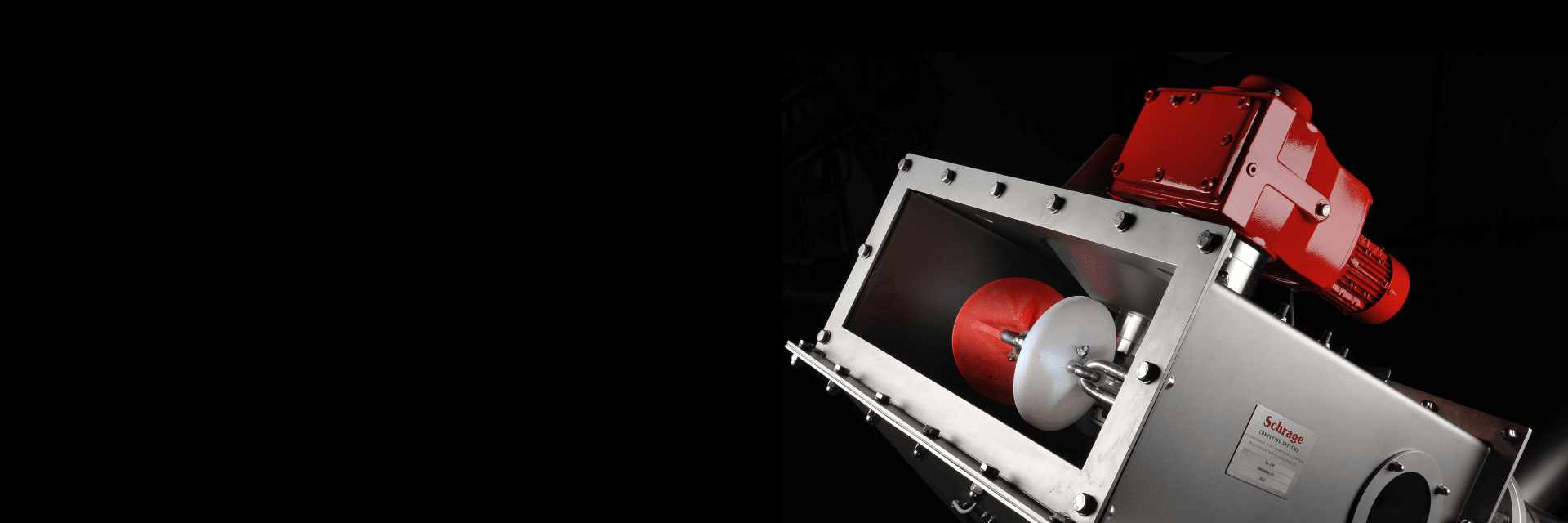

35 years of experience with our energy-saving solution

We’ve implemented numerous projects with a much higher energy efficiency to date, with our Tube chain conveyors sometimes requiring a mere 10% of the energy that pneumatic systems consume. In other words, you can save up to 90% on energy in comparison to pneumatic systems.

Are you interested in learning more about Schrage’s energy-saving solution? We’re here for you! Simply fill out the contact form and send it to us and we’ll get back to you shortly afterwards with a quotation or consultation information.

Materials handling is a subdiscipline of mechanical engineering that deals with design, planning, and construction of systems used to convey unit goods (pallets, boxes, etc.) and bulk materials (sand, grains, etc.). As a general rule, conveying liquids and gases by means of pipes does not form part of the field of materials handling.

“Materials handling” is commonly understood to refer to the actual technology involved (conveyor systems in a broad sense, i.e., including storage technology), but it also includes devising the processes involved in operating the corresponding systems. In other words, the field of materials handling covers all conveying, handling, and storage activities and processes, both in technological and business terms.

Materials handling deals with the internal transportation of goods, e.g., at ports and airports, in mines, and at manufacturing plants.

In-house transportation systems are counted among the elements covered by the field of materials handling, and include continuous conveyors and intermittent conveyors.

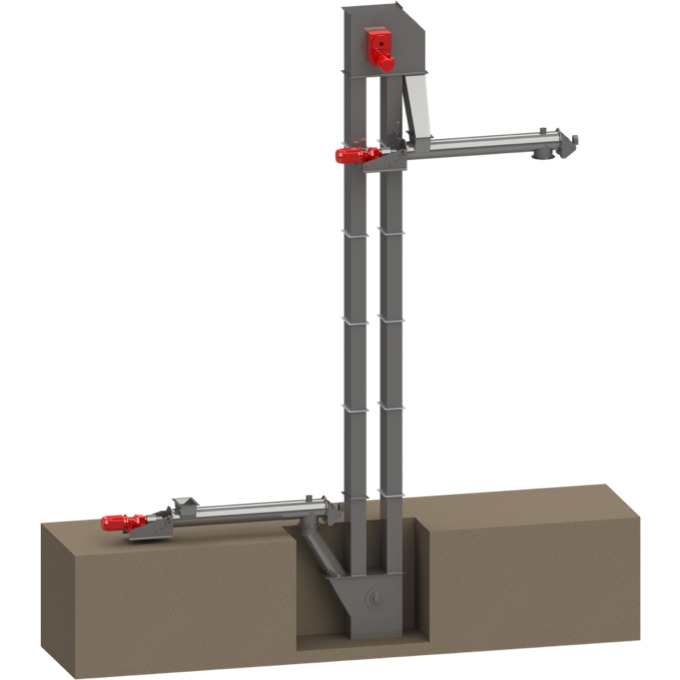

Continuous conveyors are distinguished by the fact that they continuously move the materials from a feeding station to a delivery station. This is achieved by means of continuous loops of conveyor chains and conveyor belts or with pushing or vibratory conveyor equipment. Continuous conveyors include, but are not limited to, tube chain conveyors, belt conveyors, bucket elevators, and trough chain conveyors.

On the other hand, intermittent conveying methods are characterized by the fact that there are breaks between transportation activities. Intermittent conveyors include, for instance, lifting equipment of all types, e.g., cranes, block and tackles, excavators,

and much more.

With the three-dimensional layout and the different customizable tube diameters and components it is possible to design virtually any kind of haul way, regardless of its direction. Tube chain conveyors are very easy to handle and thanks to its modular design they can be perfectly adapted to meet the on-site requirements. Unlike other conveyors they can easily be used for vertical conveyance and reach 100% of their calculated capacity.

Due to the enclosed design, the bulk materials are transported in a dust, gas, and pressure tight manner. This keeps the environment and plant clean and none of the bulk material gets lost. The enclosed design also keeps moisture out and thereby prevents any possible reactions of the bulk material.

Tube chain conveyors are used wherever bulk material quantities of up to 60 m³/h are transported over a distance of up to 50 m horizontally or 30 m vertically.