Accessories

{{ filterCounter }} Entries

For

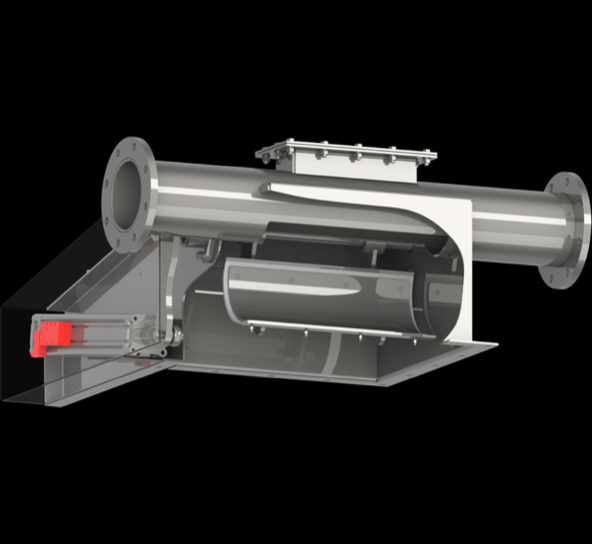

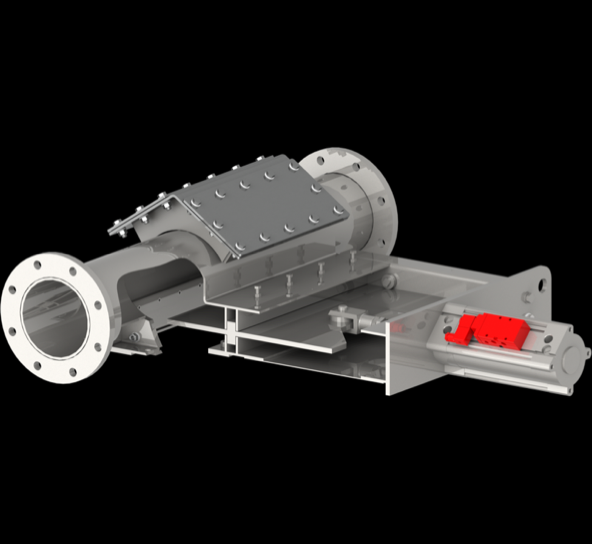

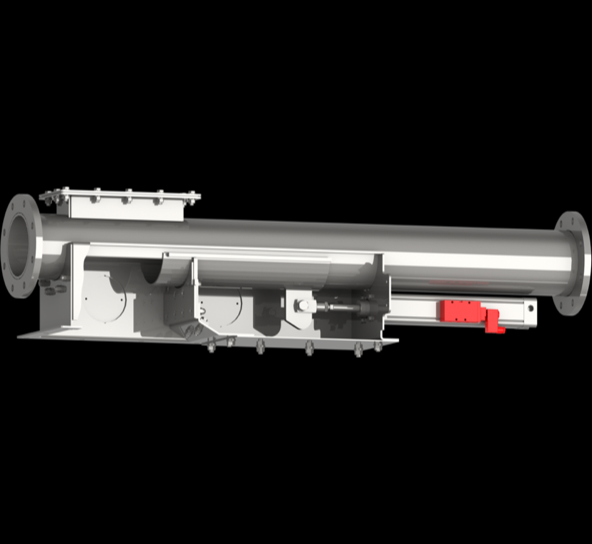

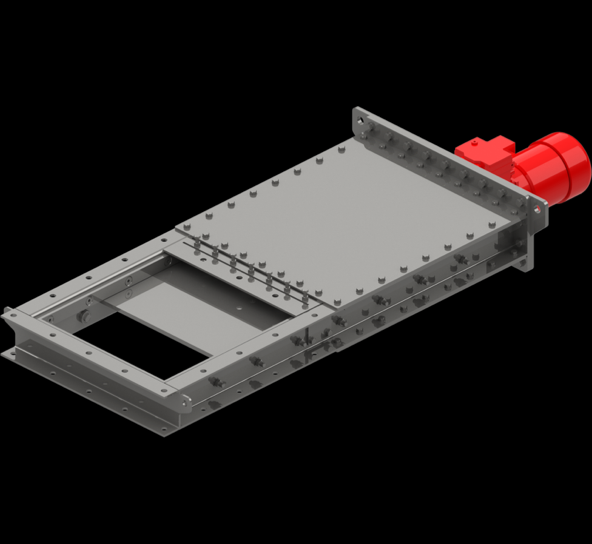

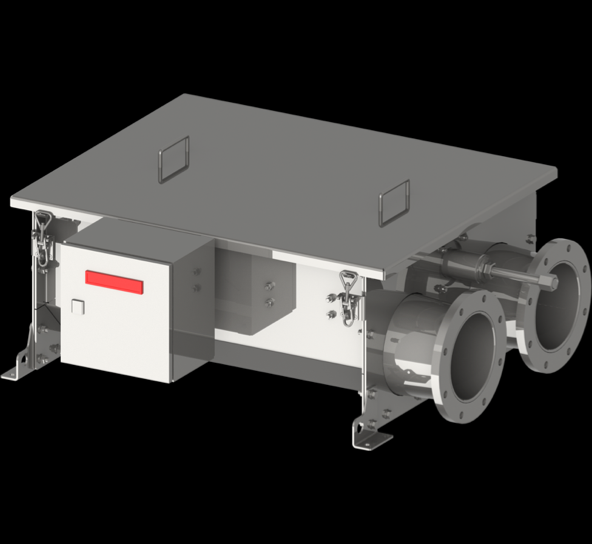

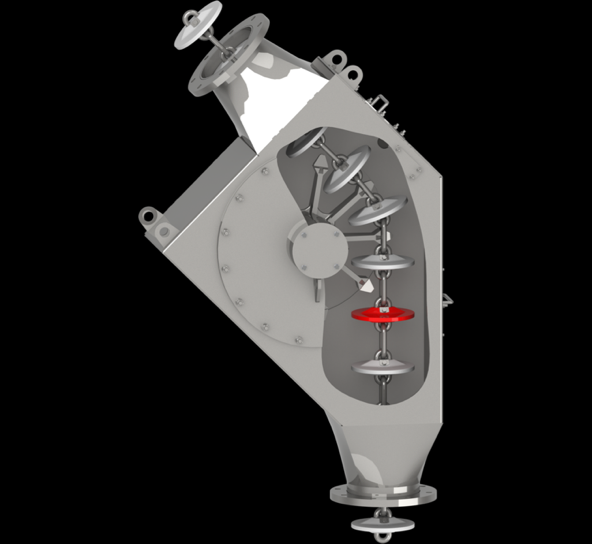

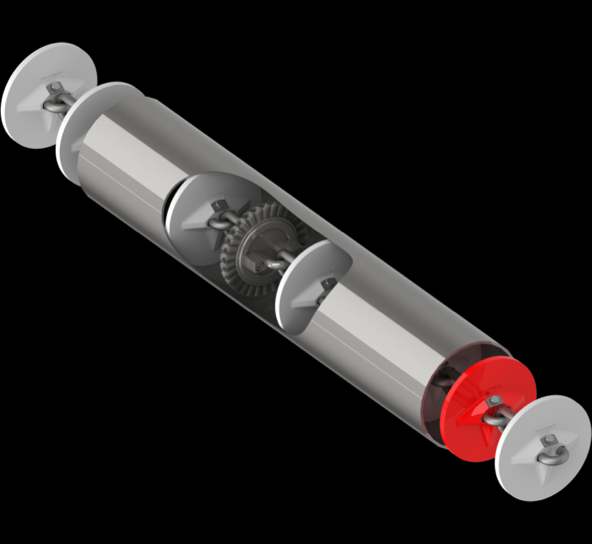

Shut-off-Systems

Depending on the properties of the bulk material, different shut-off systems are available. The highest priority is given to optimum residual discharging and a design that is free of dead space. Several options, such as vibration, spray, or rinsing systems are available for forced discharge.

Flap valve

COMPATIBLE WITH

Tube flat slide valve

COMPATIBLE WITH

Tube slide valve

COMPATIBLE WITH

Flat slide valve

COMPATIBLE WITH

Chain tension display

COMPATIBLE WITH

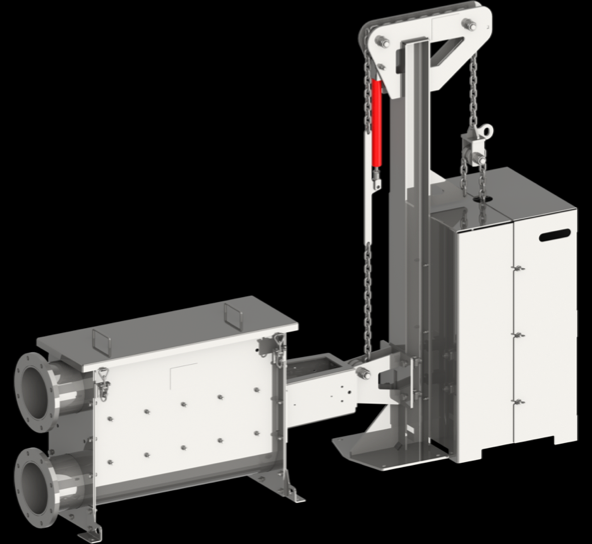

Tension station upright with weight box

COMPATIBLE WITH

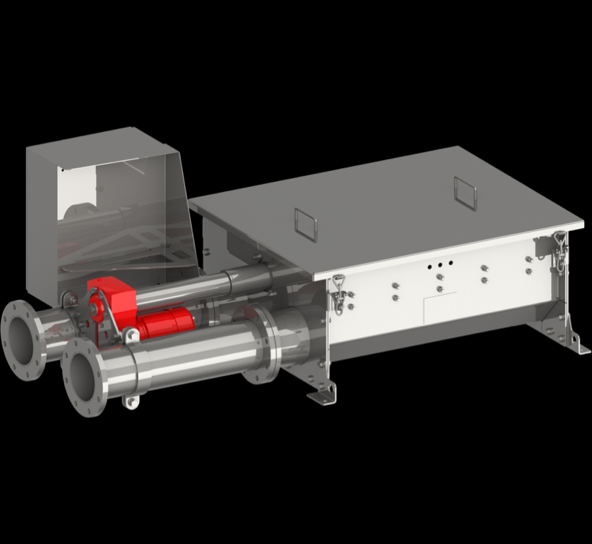

Automatic electromechanical chain tensioning device

COMPATIBLE WITH

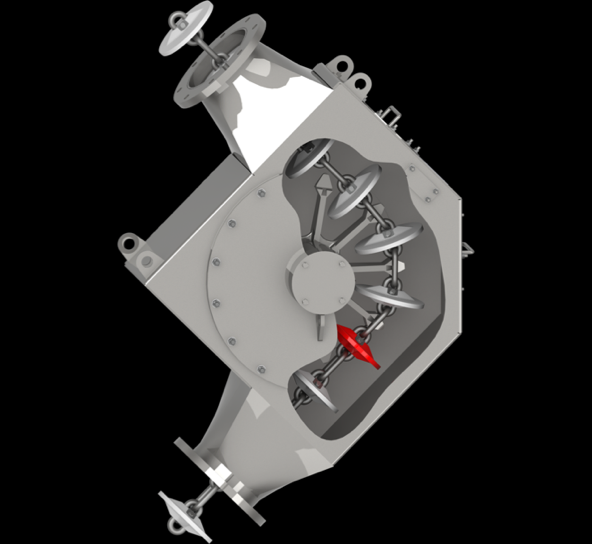

Turning Systems

Any kind of change in direction, depending on the conveyed medium, will cause increased friction, noise, and wear. In some cases, turn stations with rims or chain wheels provide a good solution.

Turning Systems

COMPATIBLE WITH

Turn station Type-P

COMPATIBLE WITH

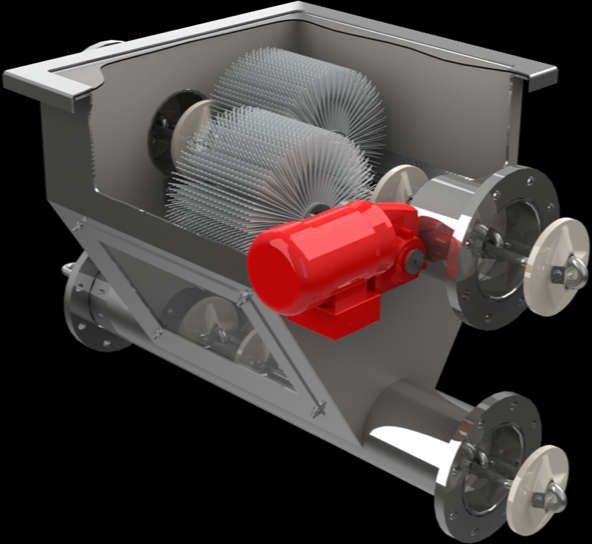

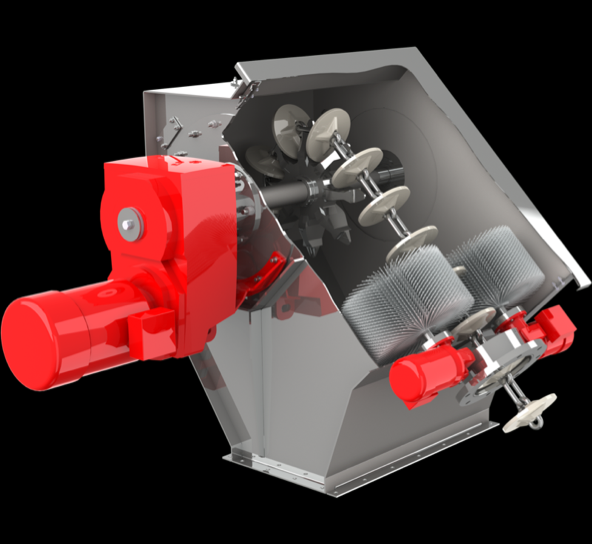

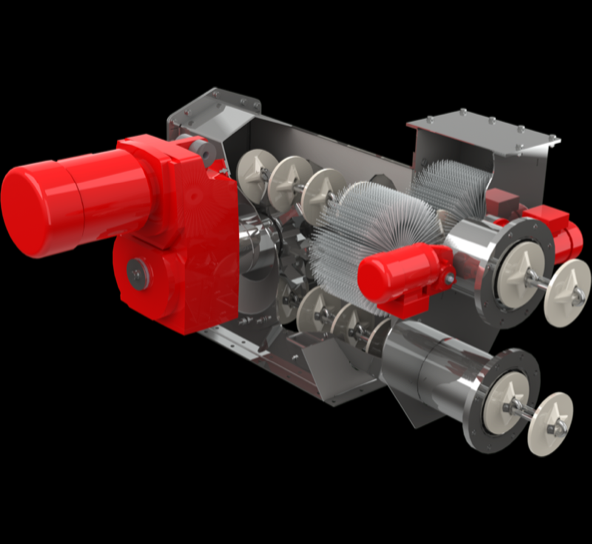

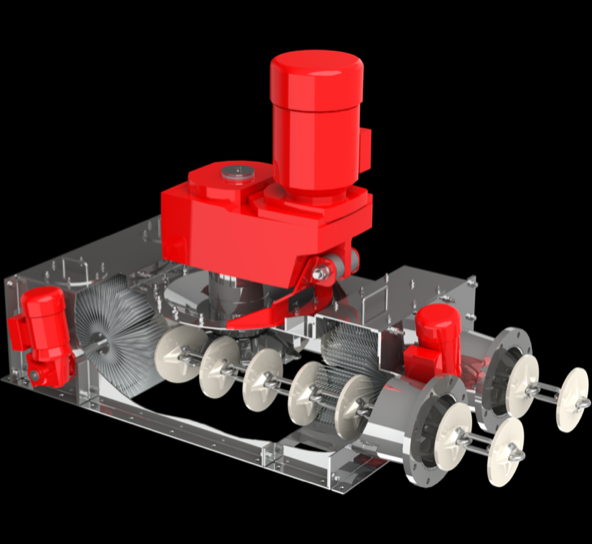

Cleaning Systems

Adhesive products can easily be removed by means of scraping sprockets, cleaning discs, or brush cleaning systems.

Scraping sprocket

COMPATIBLE WITH

Cleaning discs

COMPATIBLE WITH

Brush cleaning station

COMPATIBLE WITH

Brush drive station vertical

COMPATIBLE WITH

Brush drive station upright

COMPATIBLE WITH

Brush drive station horizontal

COMPATIBLE WITH

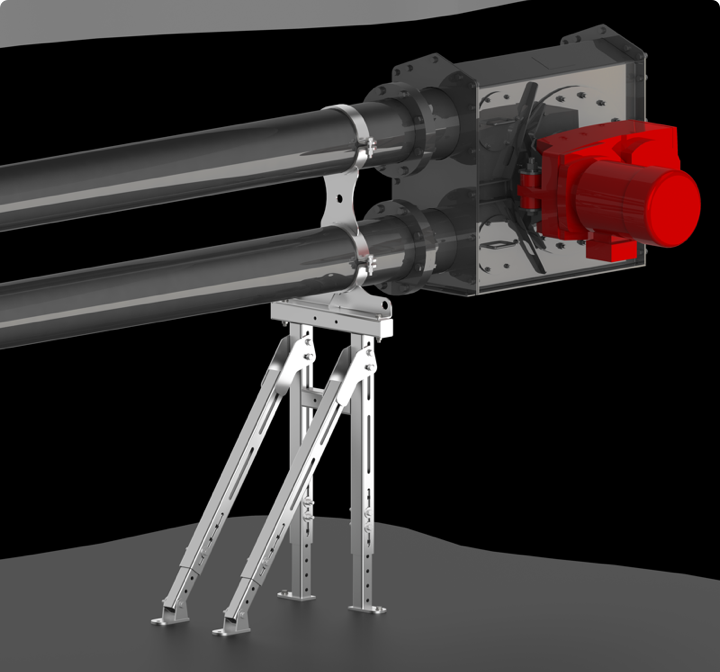

Supports

COMPATIBLE WITH

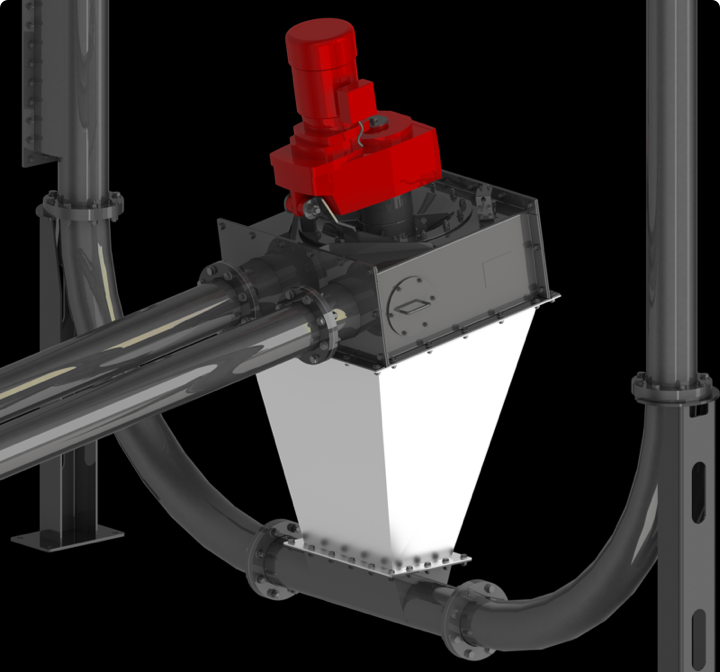

Transfer chute

COMPATIBLE WITH

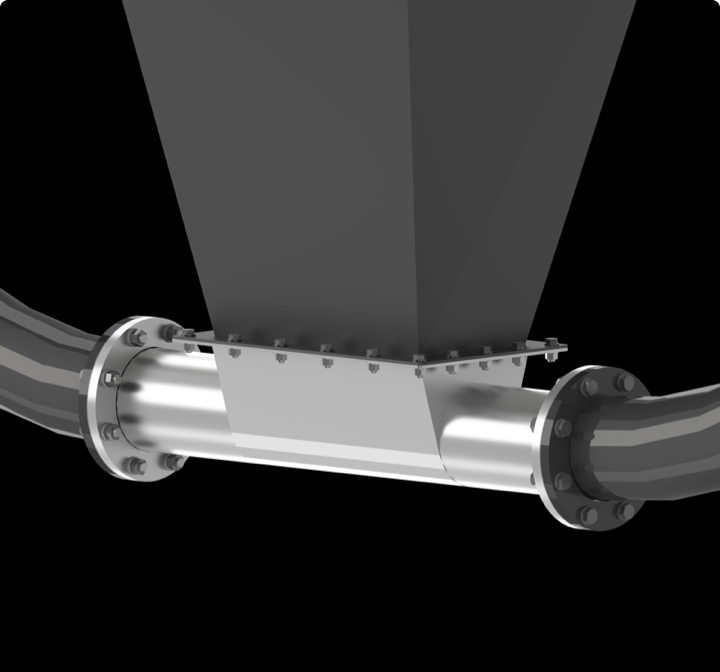

Inlets

COMPATIBLE WITH

Control

COMPATIBLE WITH