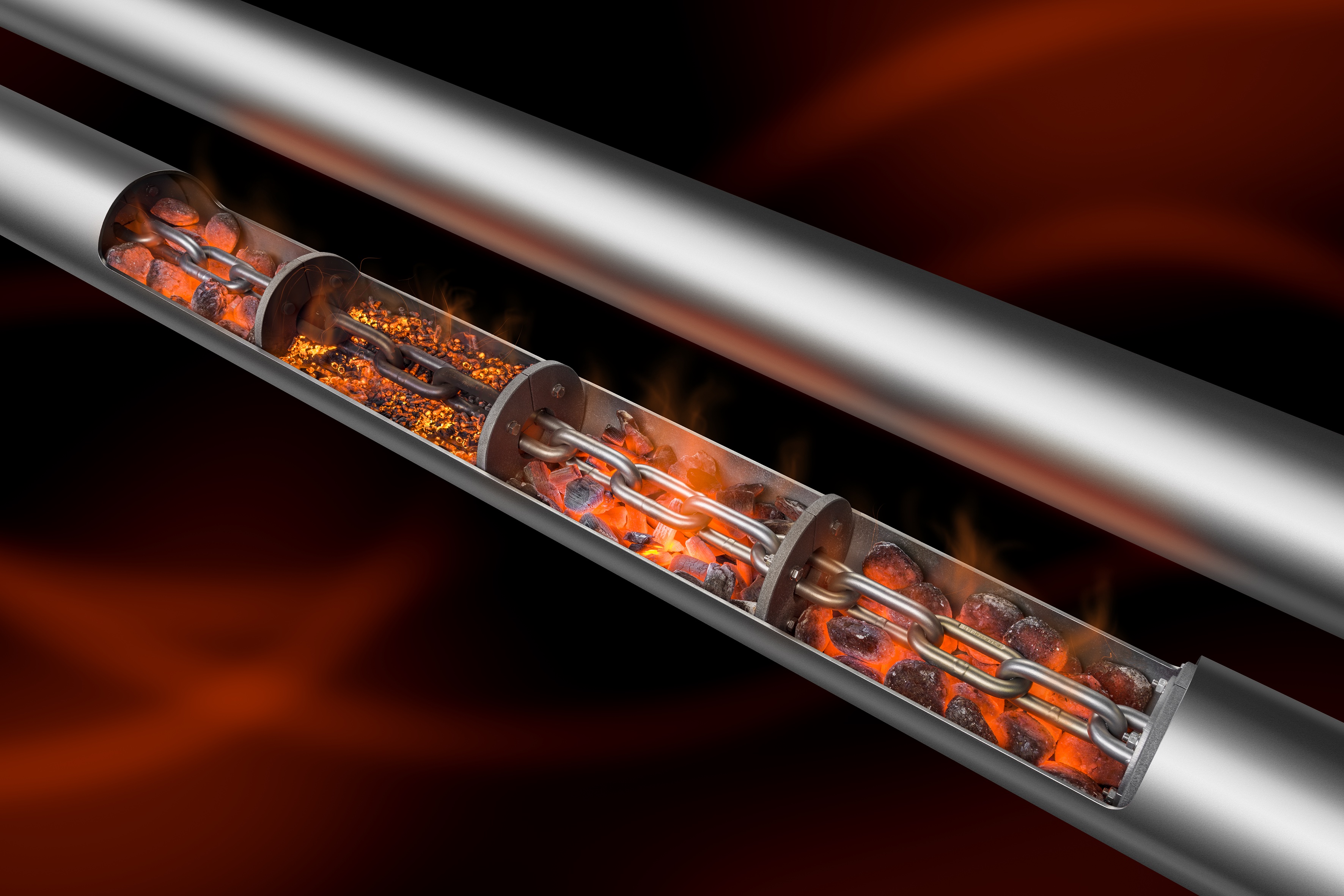

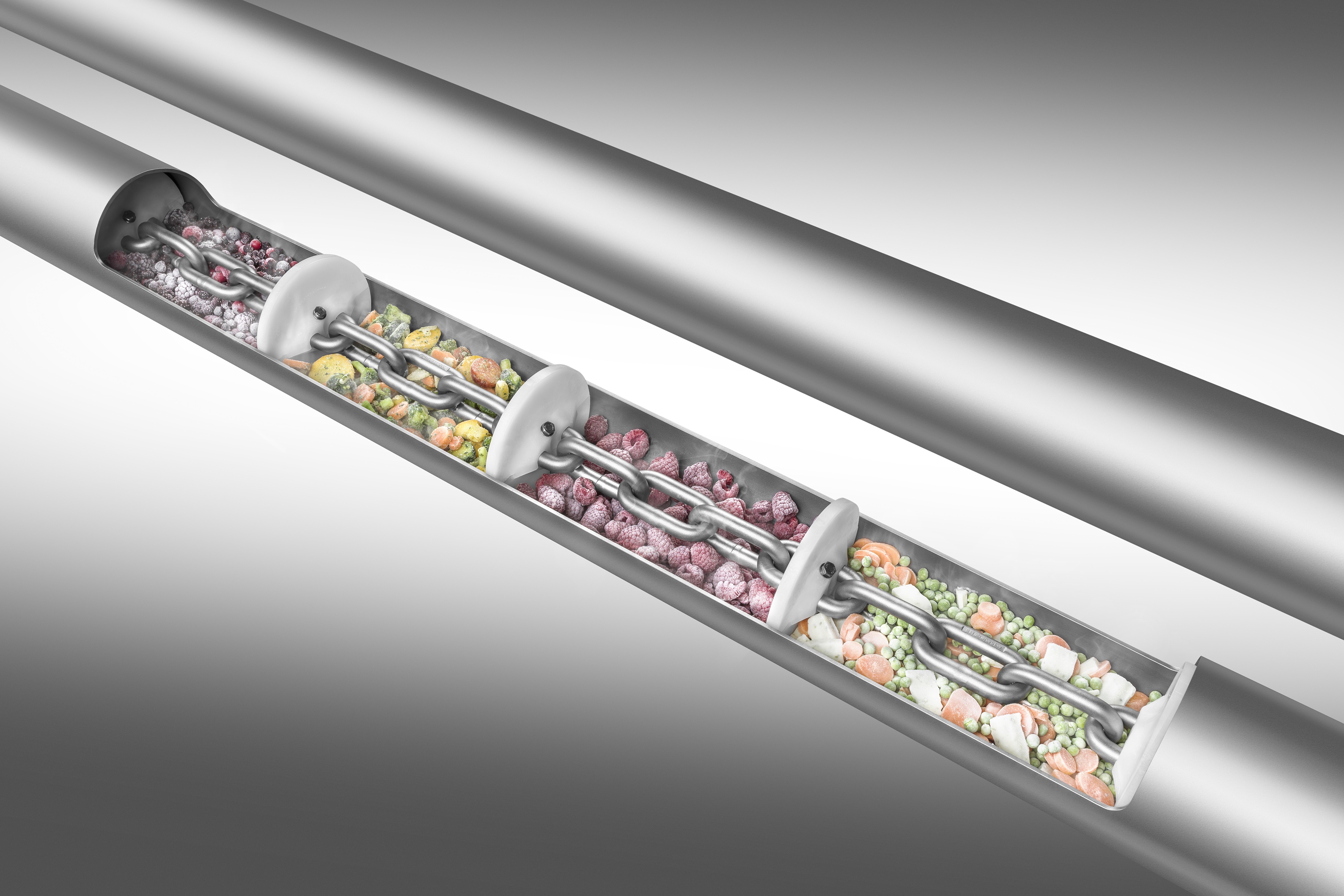

Hot & cold

- Compact conveyor technology

- Flexible line layout

- High level of self-cleaning

- Low grain destruction

- Dustproof, gas-tight, or pressure-tight

- Long service lives

- Low maintenance

Filter discharge

Pretty cool.

When it comes to applications involving temperatures as low as -70 °C, we make sure to rely exclusively on select materials that will not become brittle, break, or crack when subjected to extreme cold. And in order to ensure optimal operating temperatures, we use insulation in order to maintain constant cool temperatures and add trace heating to electrical components.