Silo, filter & BigBag

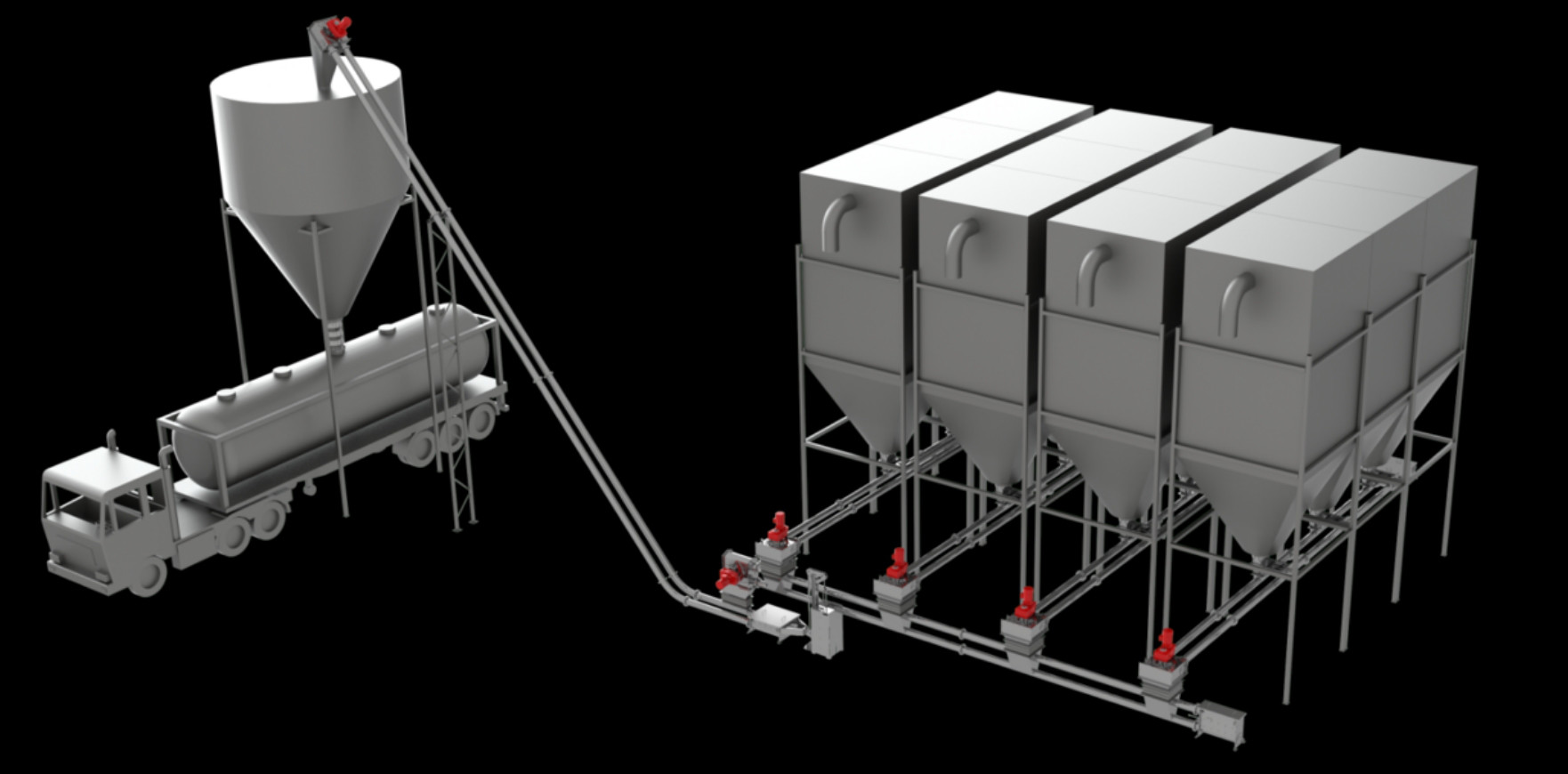

Silo filling

The best mix!

Our patented Schrage solution for the uniform mixed filling of silos reliably prevents even the most challenging bulk materials from becoming segregated. Our conveyor runs right through the silo, depositing the corresponding material down softly on the topmost level of accumulated product. No falls from height. No segregation.

- Available in 5 sizes

- Abrasive, toxic, and chemically aggressive materials

- Weatherproof and temperature-resistant

- Homogeneous silo/hopper filling

- Three-dimensional designs possible

- Low maintenance and low wear

- Accessories available

- Low grain destruction

- Energy efficiency

- Can be started while full

- Bulk density > 2 t/m³

-

Bulk material grain sizes of up to 50 mm

- Vertically adjustable

- Height adjustable

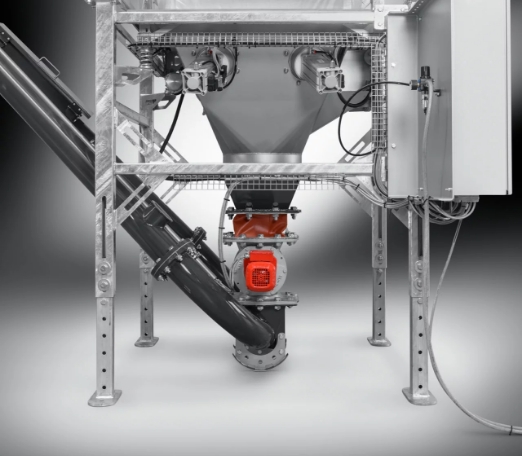

Filter discharge

Well sealed.

In contrast to other established solutions, our tube chain conveyors do their work without any encapsulation elements in order to prevent infiltrated air from sensitive filter systems. The corresponding tubes feature a specially thick-walled design that reduces the gap to conveyor discs so that no infiltrated air can make it into the system when 100% full.

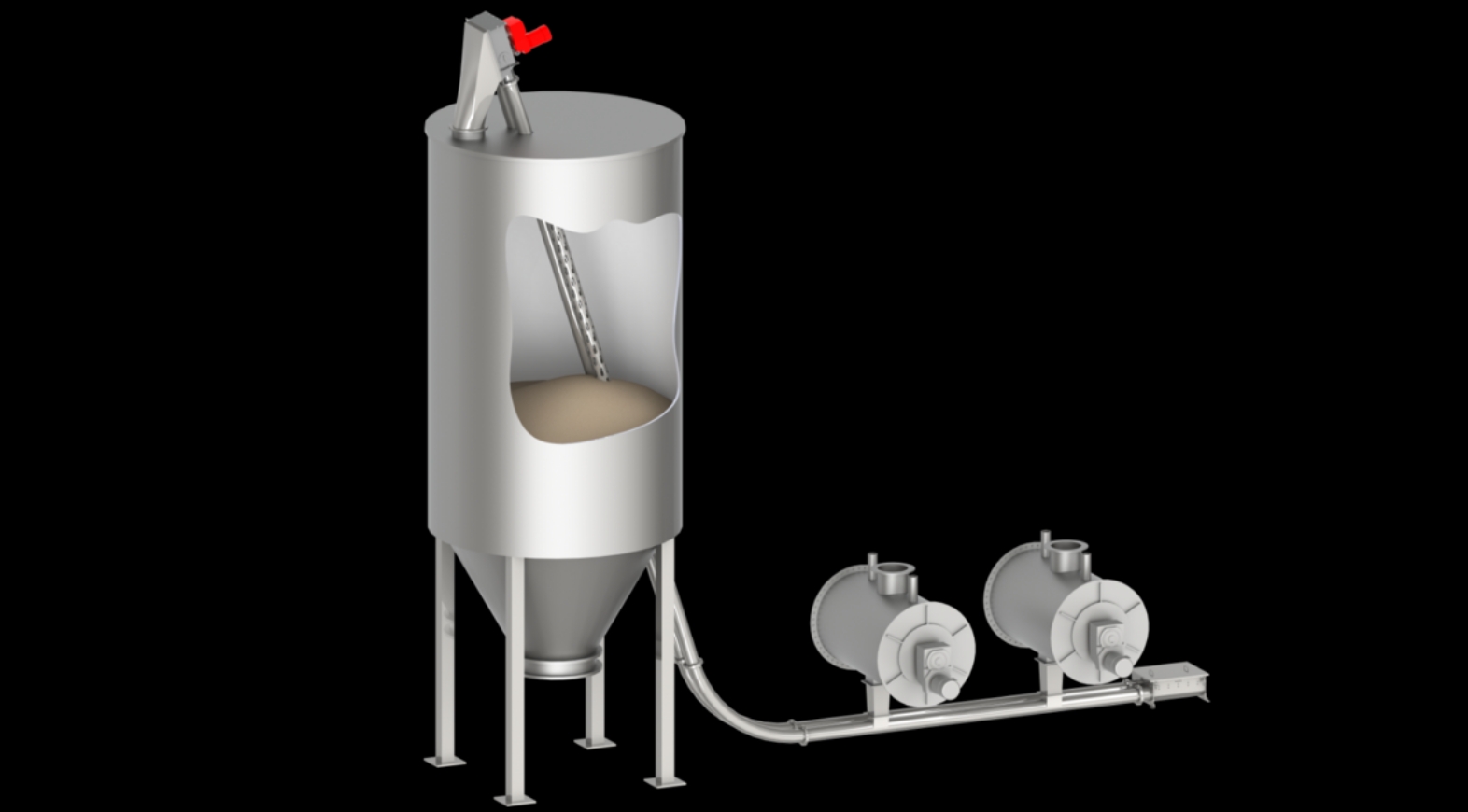

BigBag Conveyour Unit

Best of two worlds.

Customizable. Easy to operate. Our Big Bag Conveyor Unit combines the best of big bag stations and Schrage tube chain conveyors for your workflows. Gentle on conveyed materials, compact, and available in a mobile version. Add extensive accessories, and the whole thing can tackle any challenge perfectly, significantly cutting costs in the process.