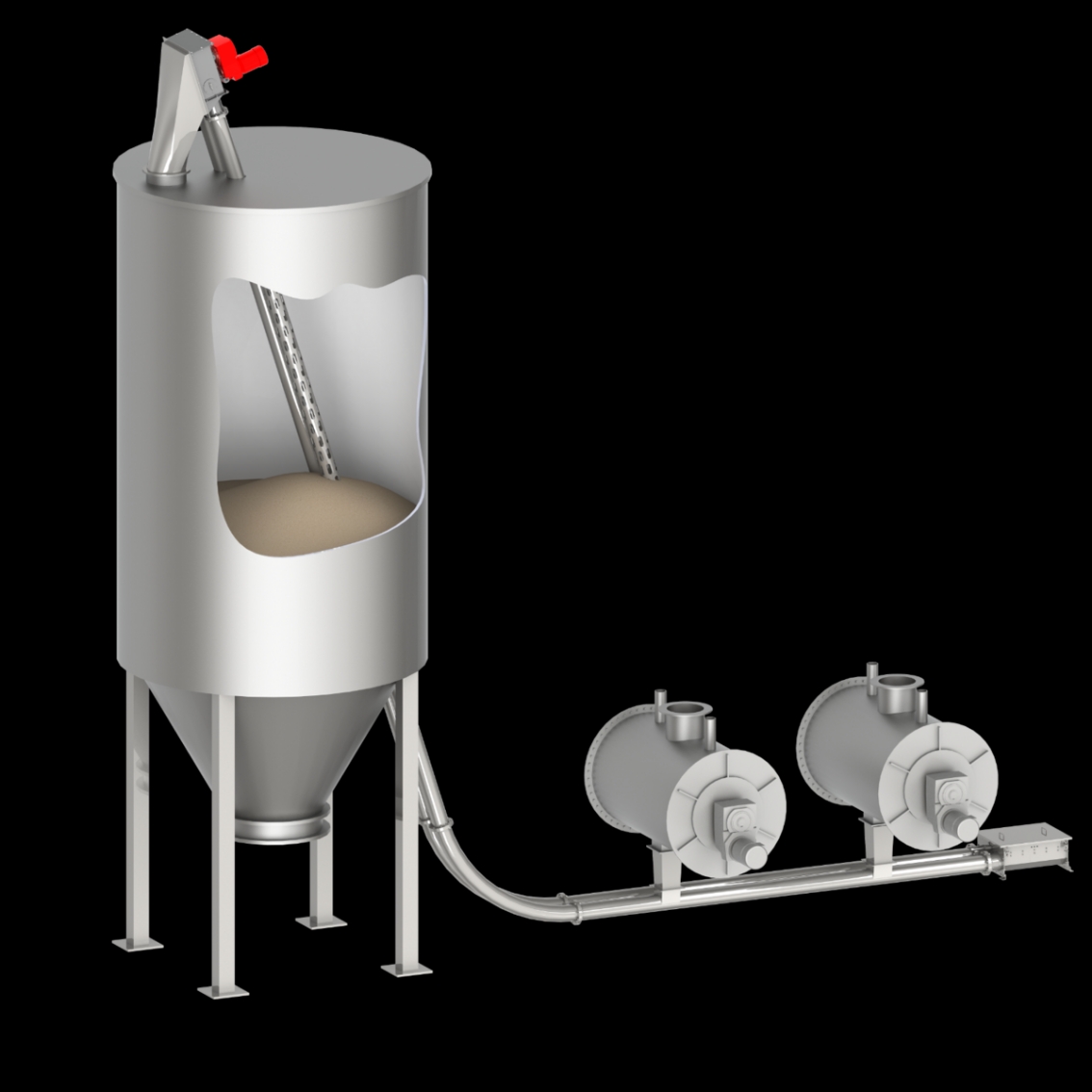

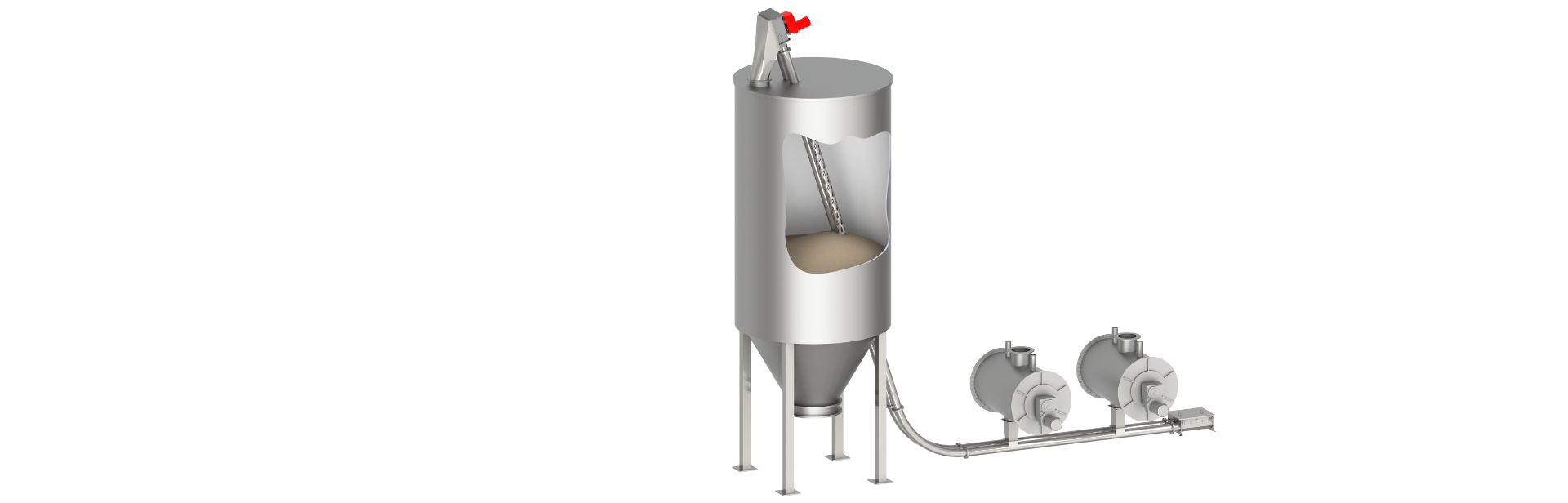

Silo filling

High conveying capacities; energy efficiency; long service lives; flexible line layouts; a design that is dustproof, gas-tight, and pressure-tight; low grain destruction; a high degree of residue emptying; and low-maintenance operation are just some of the advantages that our conveyor equipment offers. On top of this, add-ons such as temperature and moisture meters, beaters, vibrators, and fill level indicators make work much easier. Finally, insulation and trace heating can be used to prevent adhesion and temperatures from falling below the dew point.

Our patented “homogeneous silo filling” technique is the perfect solution for your needs. And in order to ensure we meet our exacting quality standards, we recommend running a conveying test with sampling at various silo levels, as this gives us the opportunity to test the pourability of your bulk materials and ensure that the system is the right choice for your specific needs.