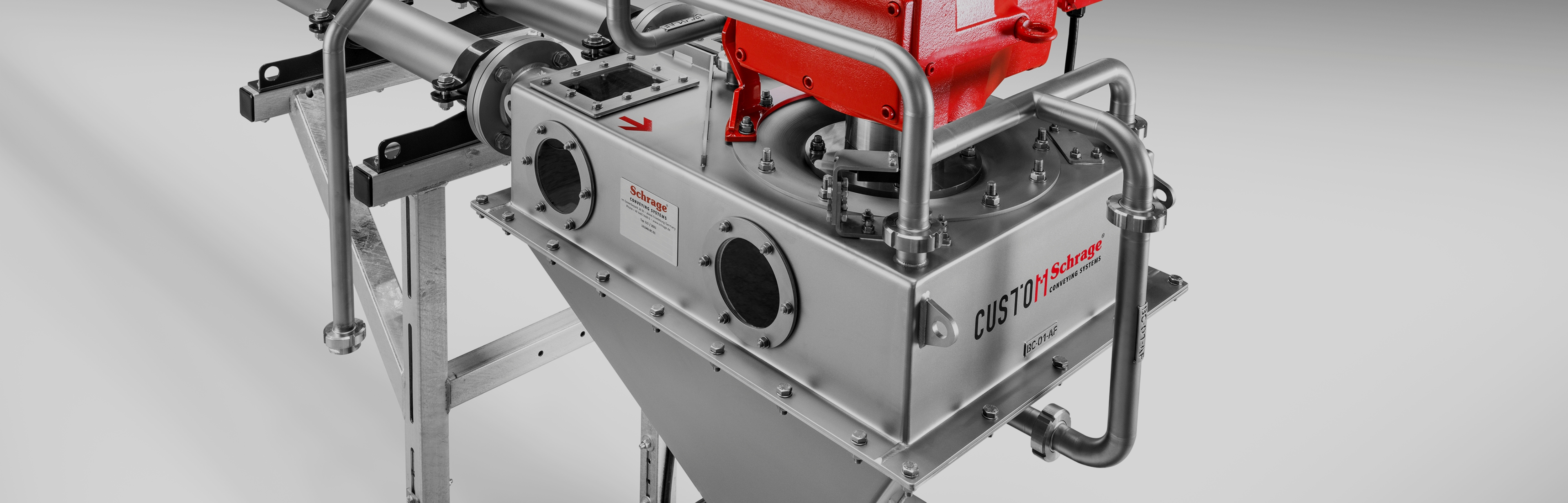

Cleanliness & efficiency

Food safety

Tasteful & hygienic.

In order to meet the needs of the food industry, we design our tube chain conveyors with surfaces that are made of corrosion-resistant stainless steel and are particularly smooth and easy to clean. Custom-built conveyor chains, food-safe greases and oils, and specially engineered conveyor discs all make sure your food will get to where it needs to be while meeting the strictest hygiene standards out there.

Seen and safe.

Strict cleanliness standards require well-engineered materials and material combinations that one can depend on. And that’s exactly why our proprietary conveyor discs for the food industry feature a composition can be reliably detected by optical foreign body sensors. This makes it possible to prevent contamination and eliminate contaminated bulk material in a timely manner.

- All components are FDA-approved or EU-approved

- Fast and easy material changes

- No disassembly required for cleaning

- Continuous use or for temporary cleaning

- CIP can be integrated

- Contamination prevention

- Food-safe materials

- Conveyor chain cleaning

- Smooth surfaces

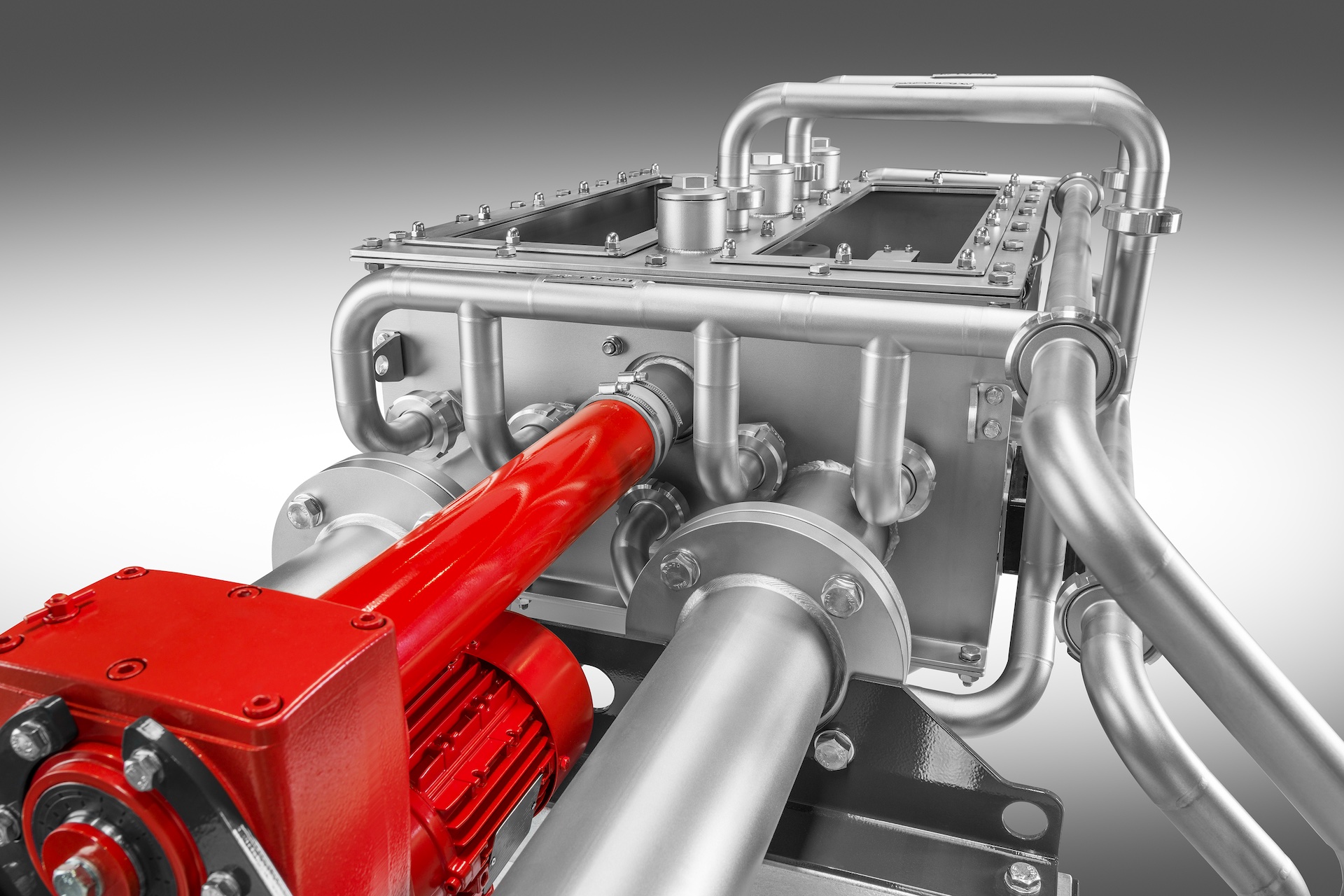

Cleaning systems

Perfectly clean.

A cleaning system can be incorporated into our tube chain conveyors as necessary for the application at hand, with the necessary number of cleaning ports being integrated into the system. These ports can then be used to pour in cleaning liquids, disinfectants, and hot liquids to reliably clean the system.

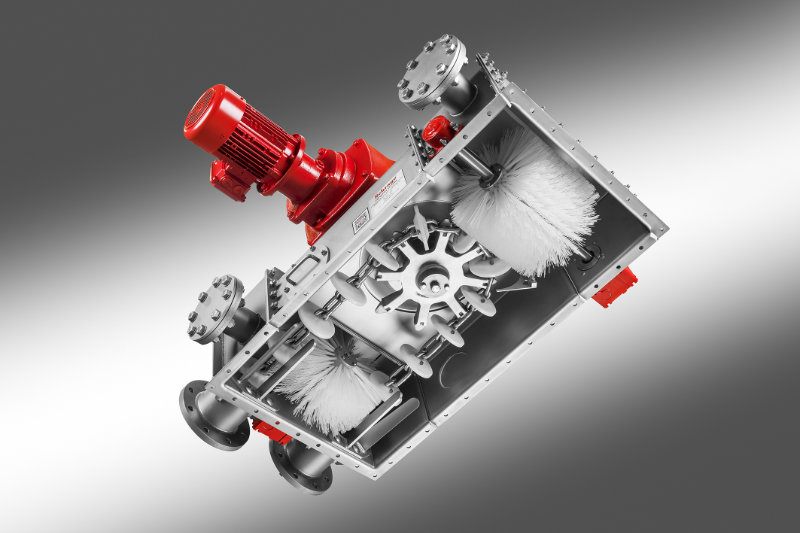

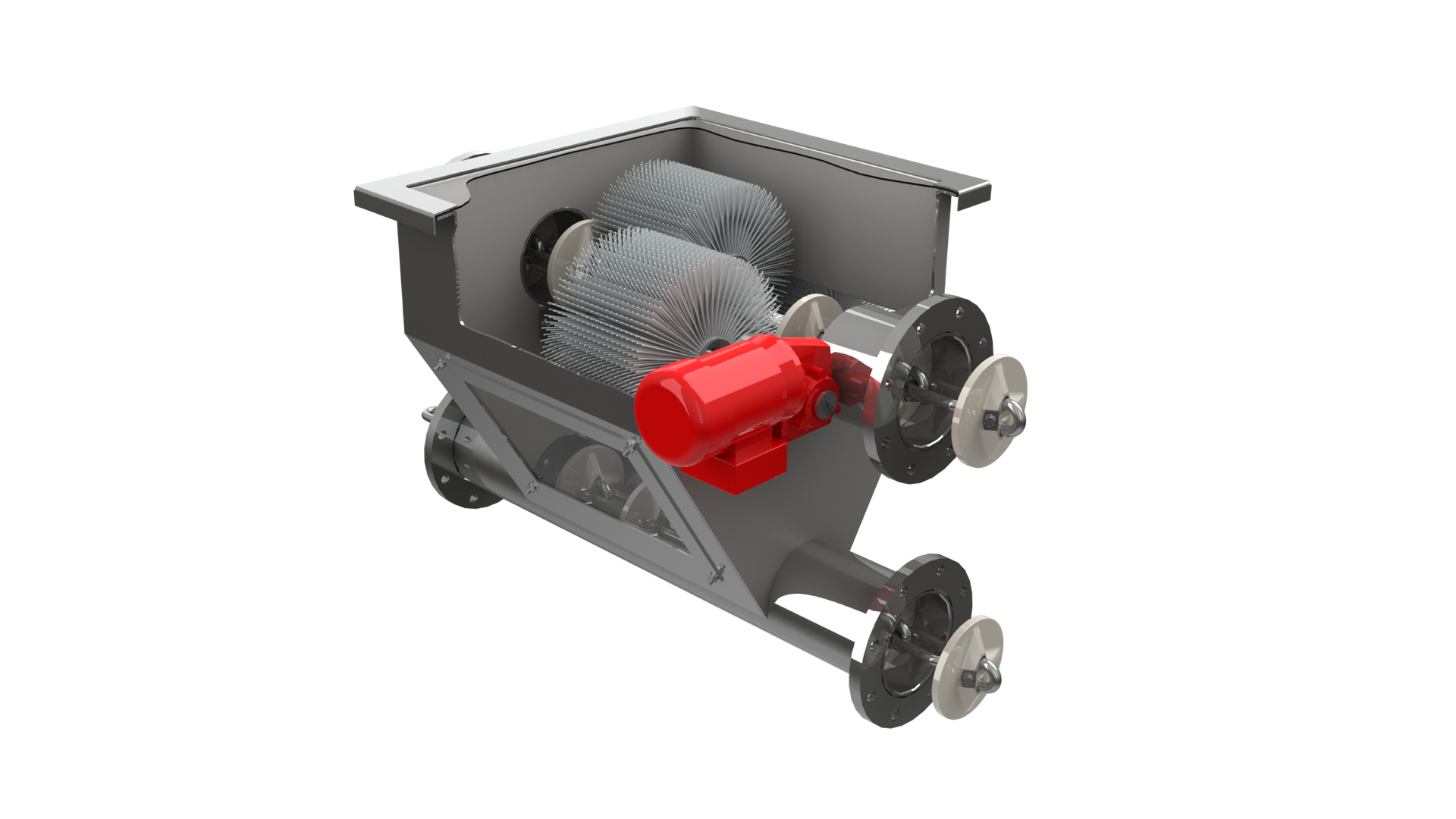

Brush cleaning station

Proper brushing technique

Challenging bulk materials that are particularly sticky, cake easily, or are difficult to remove from the conveyor chain and discs due to moisture can be easily cleaned off with our brush cleaning station. The result? Perfectly optimized material discharge and cleaning characteristics when changing materials.

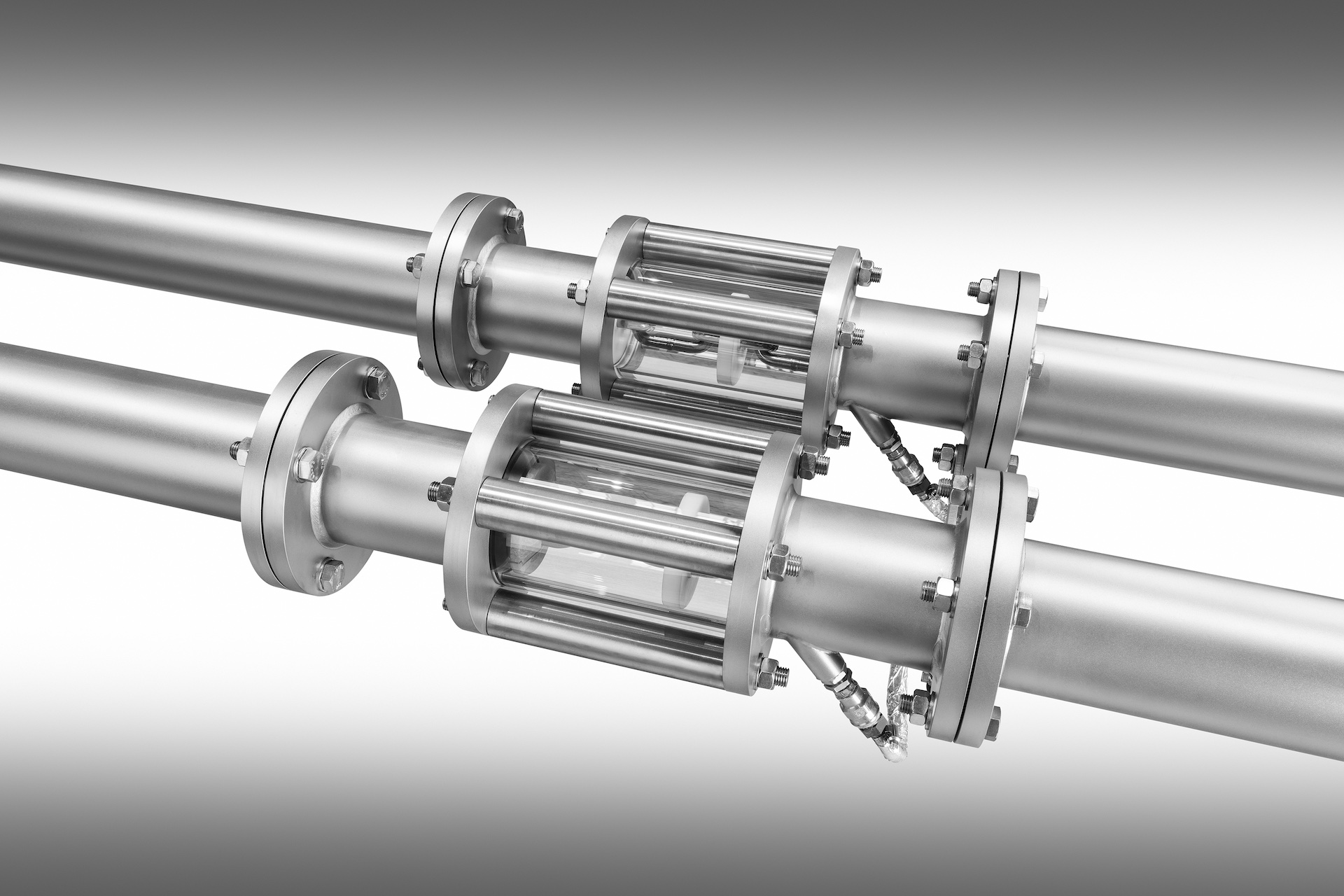

Cleaning systems

Cleaning is an inside job

In order to remove all material residue from the inside of our tubes, we can add special cleaning discs to our conveyor chains as necessary.

Oversized cleaning discs

For materials that cake easily These discs are installed at a set spacing between normal conveyor discs in order to ensure regular cleaning.