Schrage vs. Drag chain conveyors

Drag chain conveyors

- Wider inlets for bulk materials with poor flow properties are possible

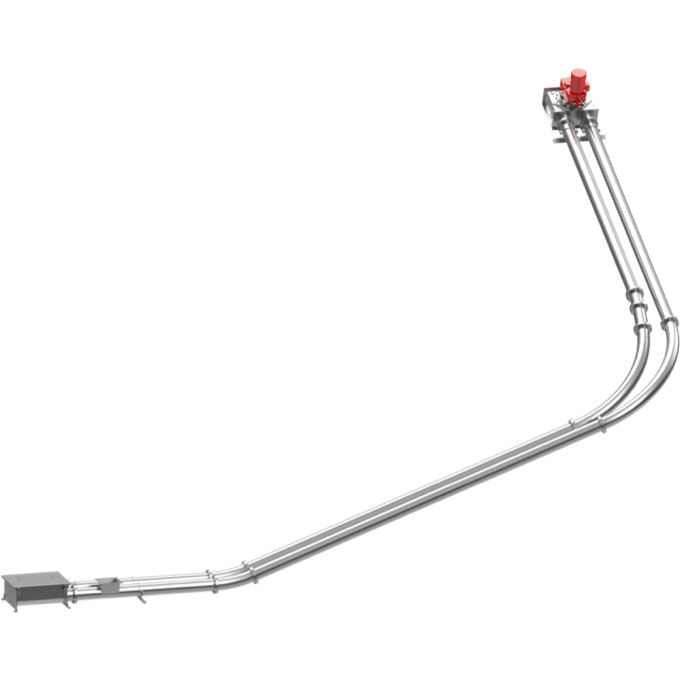

Drag chain conveyors can be used for both horizontal and vertical conveyance applications. They are continuous conveyors in which the material being handled is conveyed by a chain with flights inside a trough (without any agitation). The cross-sectional area of the material being conveyed is considerably larger than the flights. The principle according to which bulk materials are conveyed in drag chain conveyors rests on the different frictional forces at work.

If the bulk material’s internal friction (and therefore the pulling force exerted by the chain) is greater than the outer frictional forces between the bulk material and the trough wall, the material being conveyed will be moved forward. Drag chain conveyors feature the following important components: a conveyor chain with the corresponding flights (skeletal or solid) and a conveyor trough with redirecting and drive stations.