Schrage vs. Bucket elevator

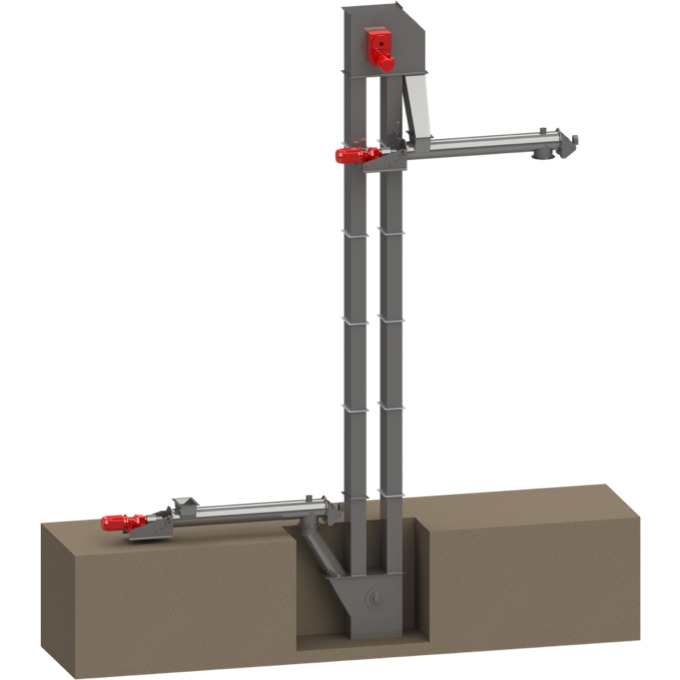

Bucket elevators

- Well-suited to coarse bulk materials

- Higher delivery rates possible

- Taller conveying heights feasible

- Reduced grain destruction under certain conditions

Bucket elevators are used to convey bulk materials vertically. V-shaped buckets made of steel or plastic are attached to continuous belts in the corresponding trunks. Bulk material is continuously loaded onto these buckets so that it can then be unloaded at a redirecting station with the use of an unloading ramp.

Depending on their overall width, their bucket capacity, and the height that must be traversed, bucket elevators can require a significantly large amount of driving power. In addition, the tare weight of the buckets and chains themselves mean that there is a limit on the aforementioned height, and conveying materials beyond heights of 120 m is rare.